High Tech Industry

Gas, liquid and vacuum applications for high tech equipment Our focus segments are quantum computing, analytical instrumentation, MedTech, life sciences, and the chemical industry.What’s in it for you?

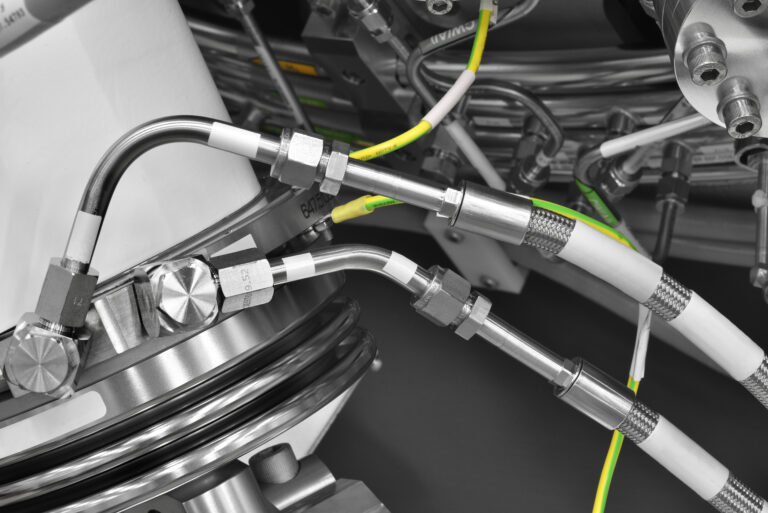

At CoreDux, we build custom artery systems for High Tech industries that demand extreme precision, purity, and reliability. Our expertise spans quantum computing, analytical instrumentation, medtech, life sciences, and the chemical industry, delivering flexible solutions for gas, liquid, and vacuum applications.

With decades of experience, we ensure our ultra-clean gas hose assemblies and engineered systems meet the strictest industry standards. Whether it’s maintaining cryogenic conditions for quantum computing, analytical and laboratory equipment. Ensuring contamination-free lab environments, or meeting stringent client specifications, our parts get the job done.

When precision matters

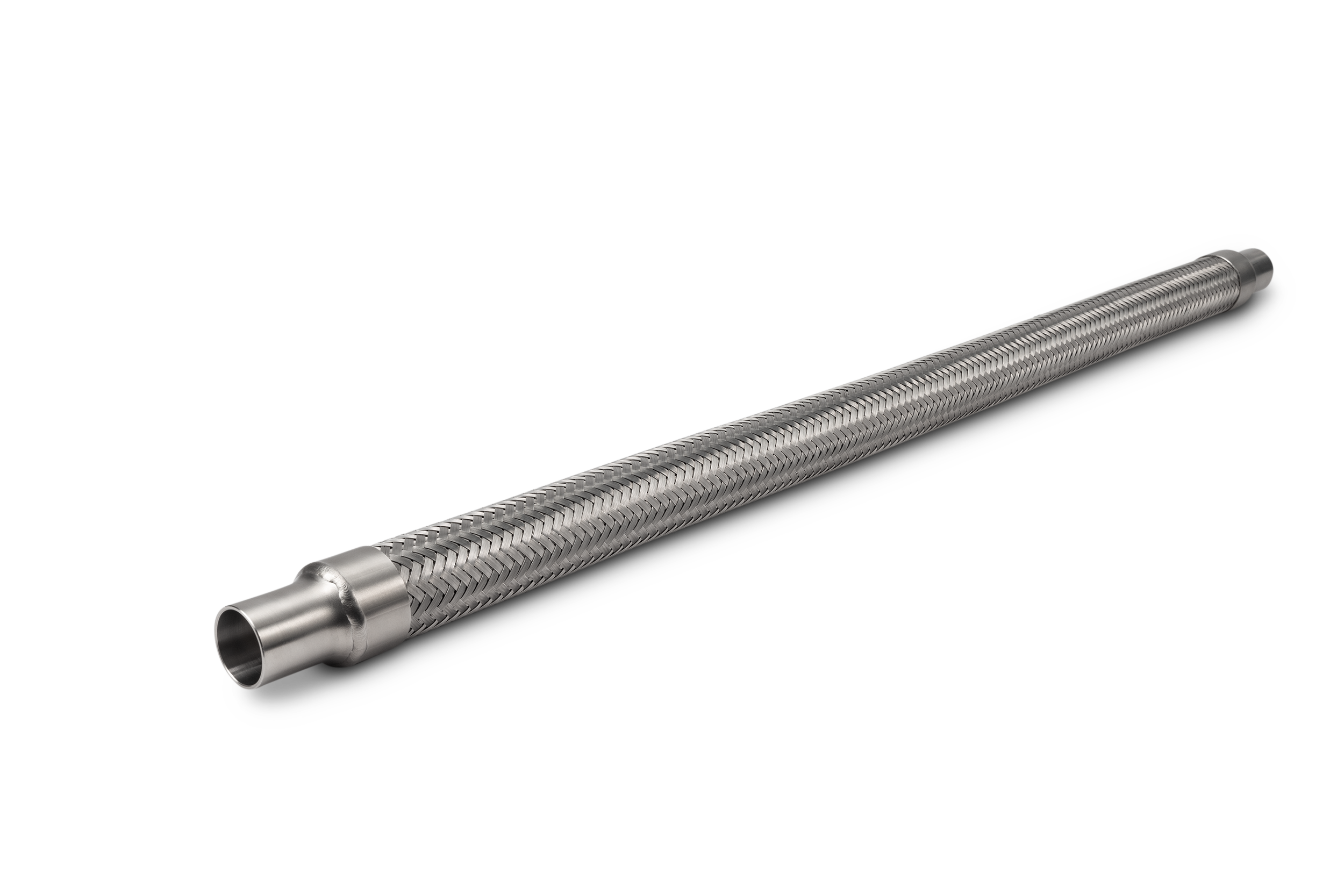

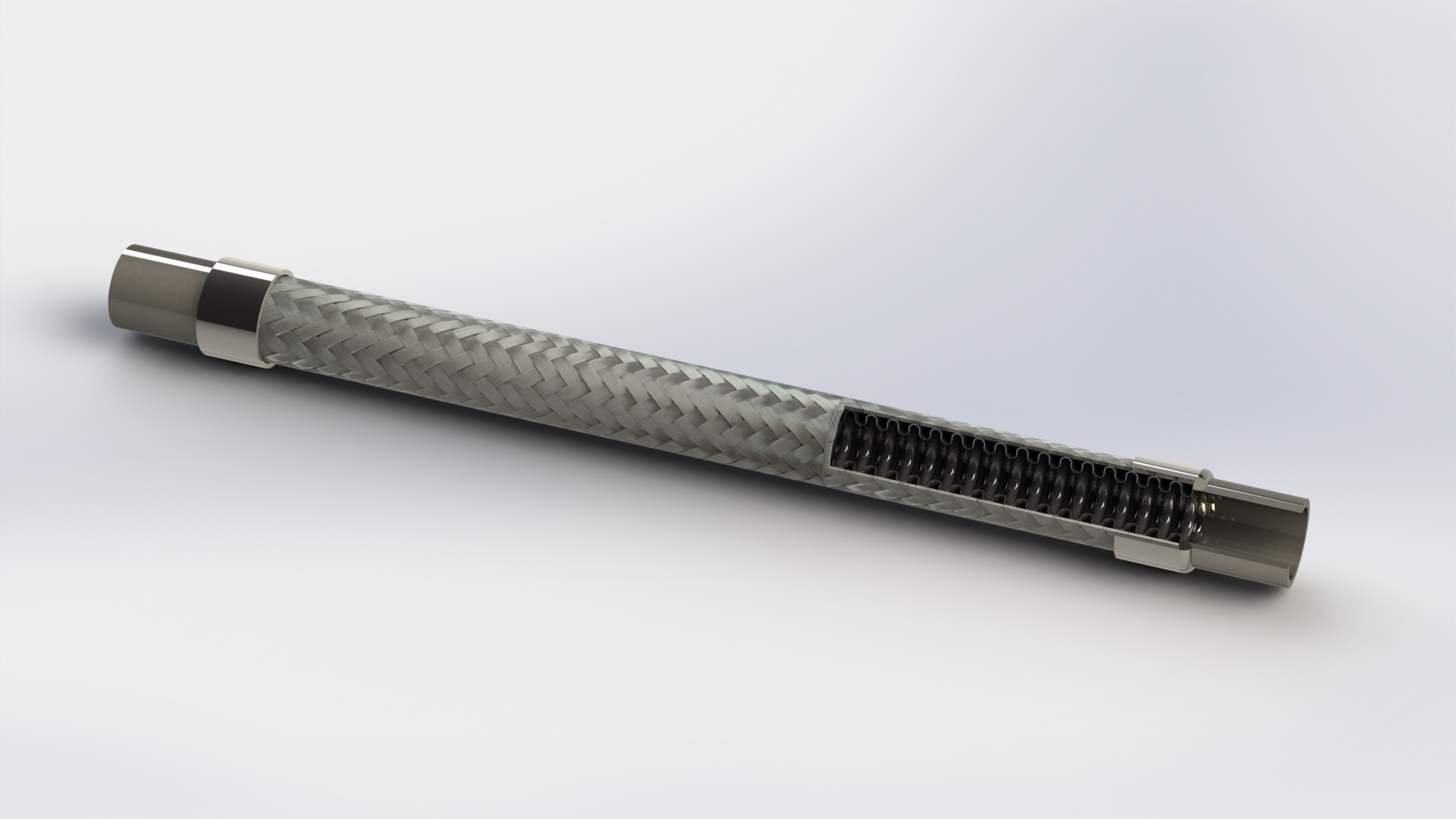

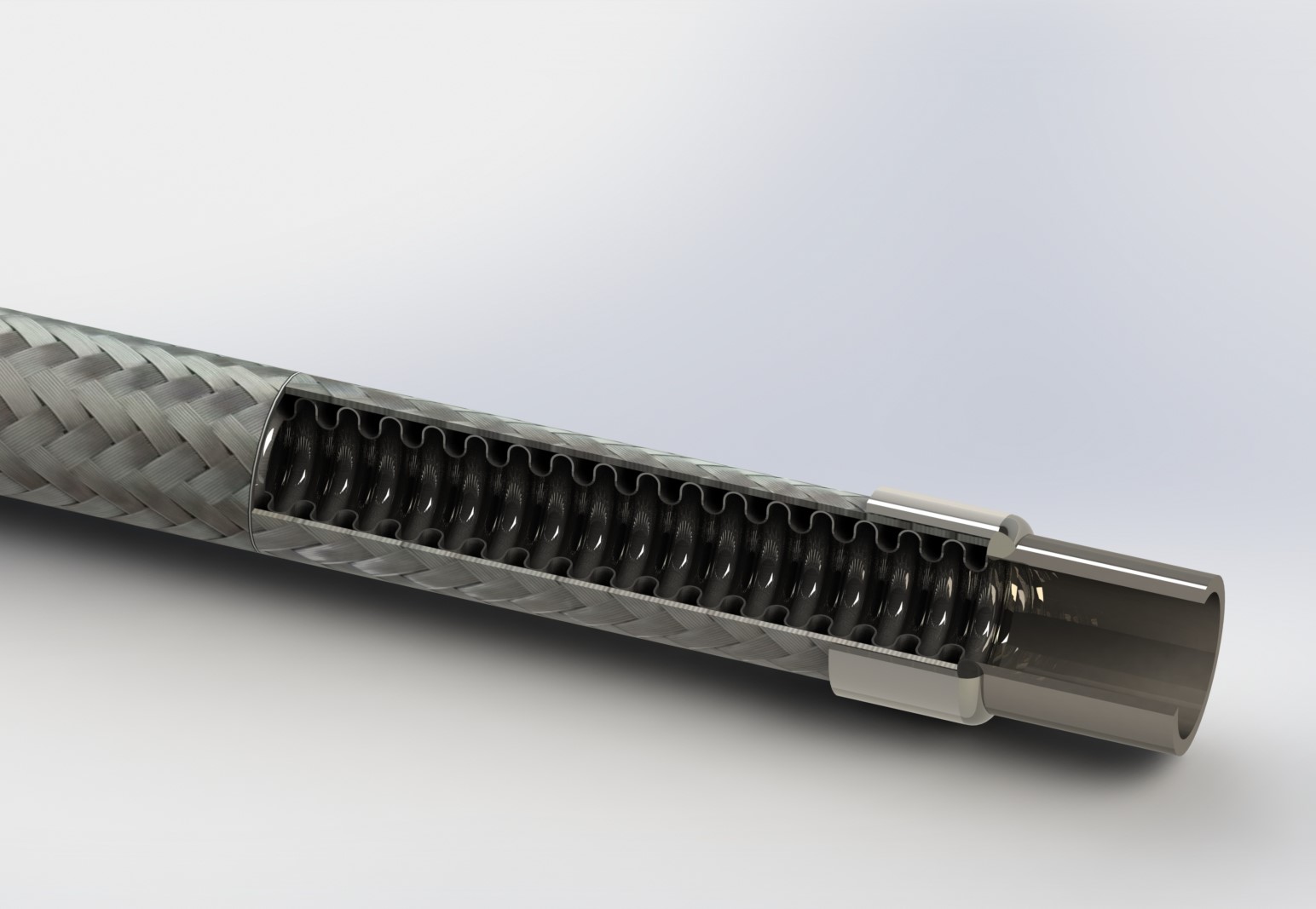

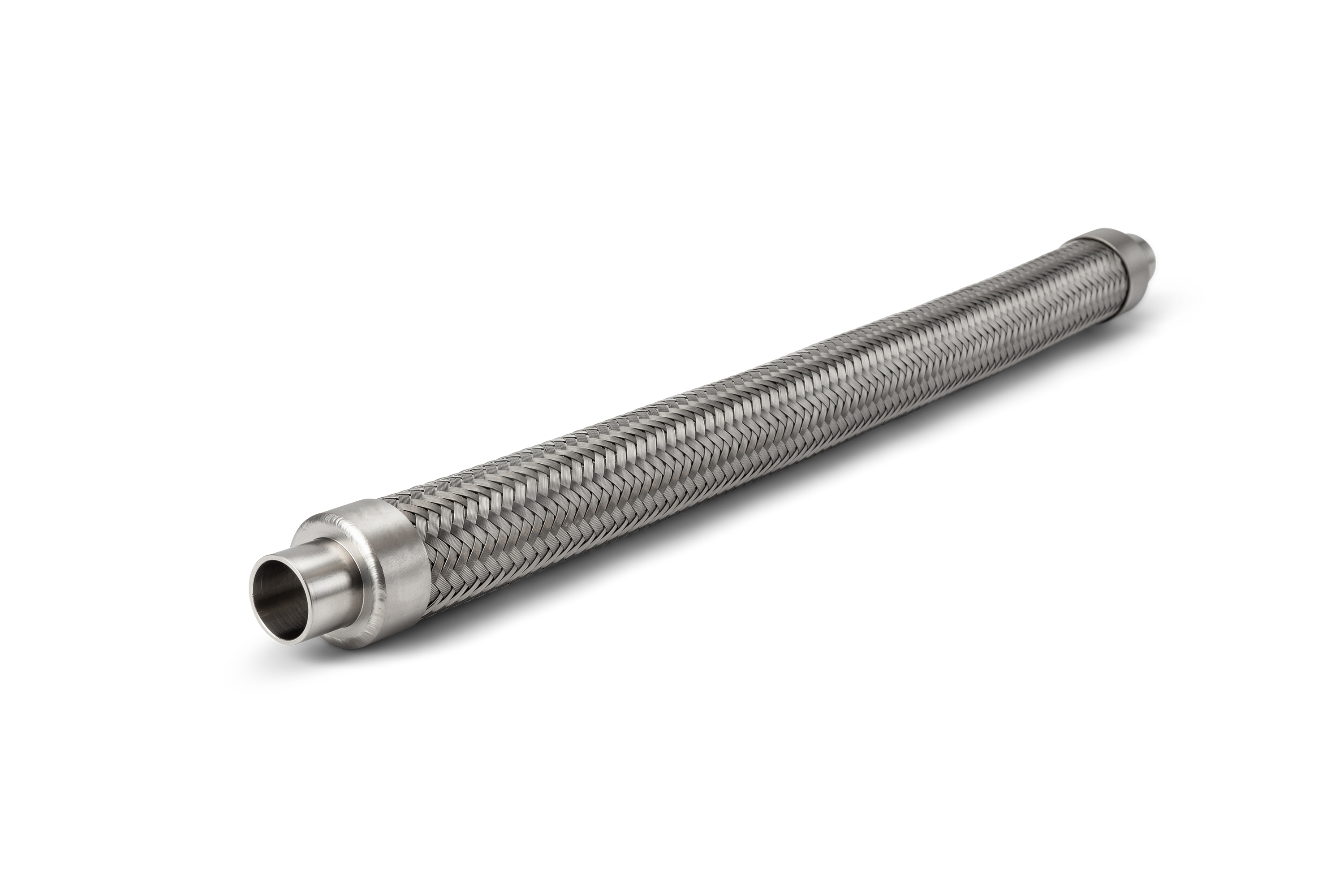

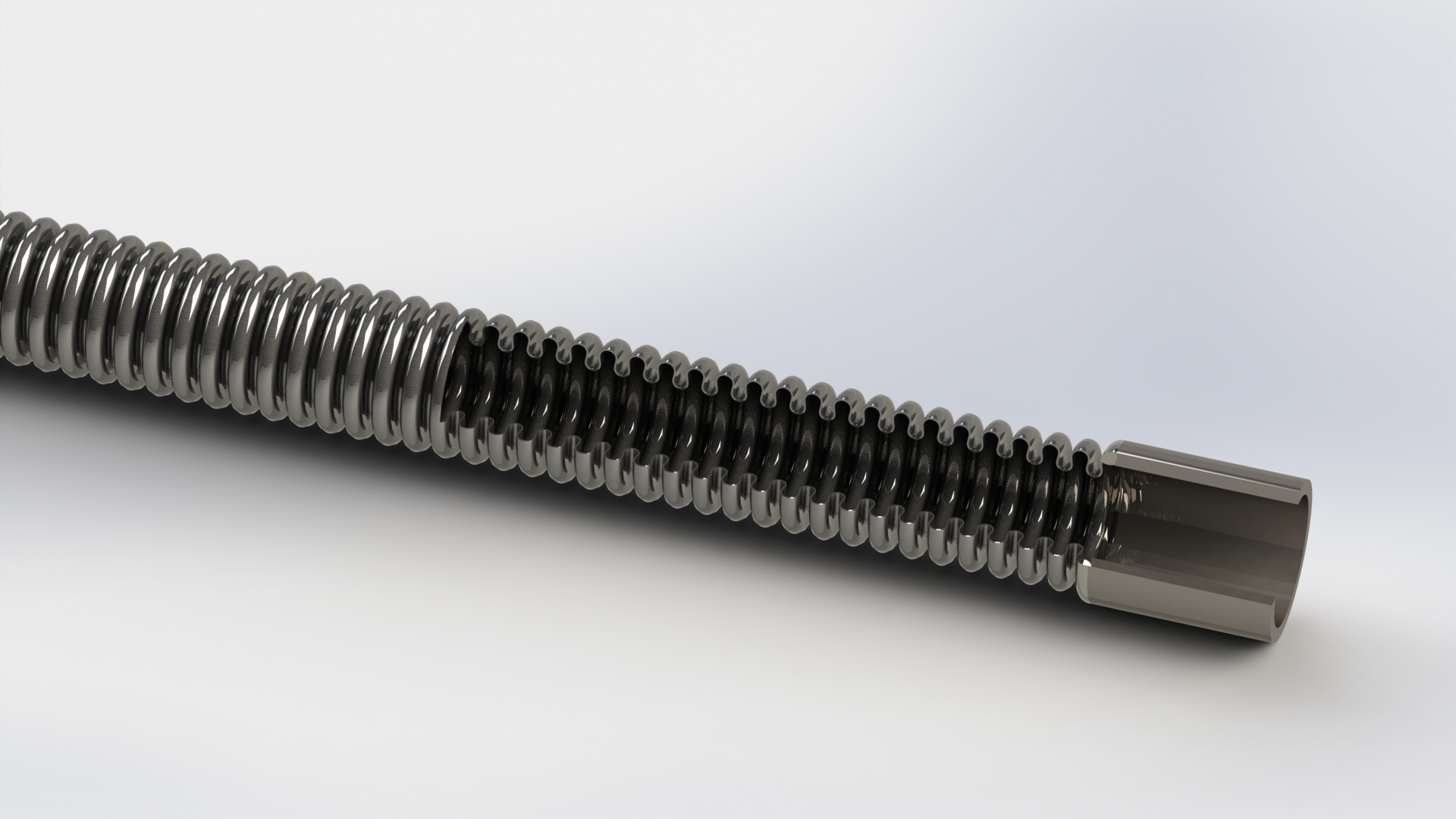

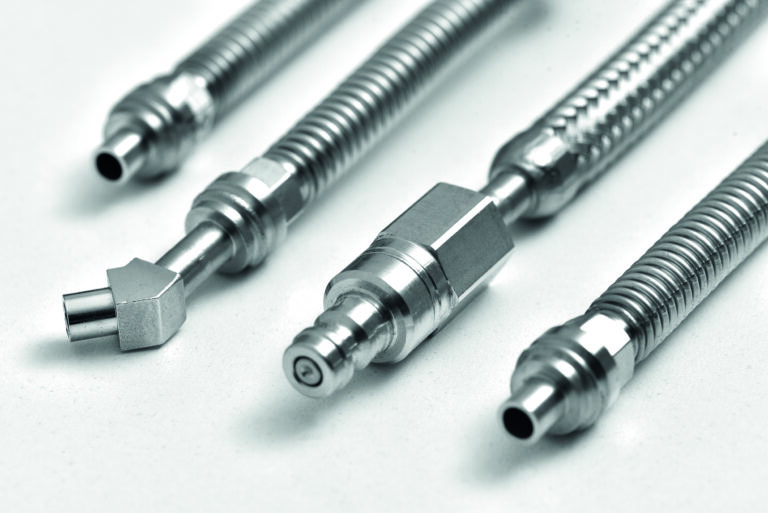

Not all hoses are created equal – materials and design matter. Our hoses come in PTFE, PFA, stainless steel, and specialty alloys, with a range of diameters, wall thicknesses, and insulation options to ensure the right fit for your application. Need custom end connections? Whether it’s butt weld ends or groove/clamp suitable, we’ve got it covered.

For industries where cleanliness is non-negotiable, our sanitary-grade fittings and specialty gas regulators (PRS & TBRS series) meet the highest standards, including FDA/USP Class VI compliance for our Copolymer PTFE. Engineered for high-purity gas handling, our hoses lock in seamlessly with sanitary clamp connections – ensuring uncompromising reliability where it matters most.

I. CoreDux Components

Catalog items and standardized parts that fit

Ranging from a well-developed standard portfolio to original equipment- and design manufacturing, We strive to be your go-to manufacturer for flexible components. As an ODM, we develop highly specific products catered to your application needs. Our product development and process roadmaps enable flawless manufacturing of tailor-made or system-specific parts.

II. Integrated solutions

From contract manufacturing to systems integration

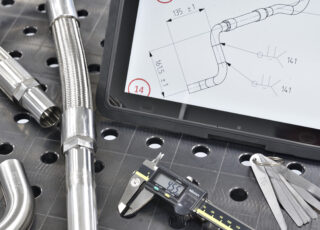

As a built-to-print or built-to-spec manufacturer, we offer both contract manufacturing and full systems integration. This means that depending on your needs and wishes, we can provide design and manufacturing or focus on the latter.

When these come together

Dual Competence, Single Source

Our sweet spot lies where we use CoreDux components to provide your systems integration. It is in this (vertically) integrated ODM proposition that we offer the most value. As an ODM for our CoreDux standard product portfolio and our proposition as a systems integrator, we have the skills, capabilities, and processes in-house to solve your challenges. We call this Dual Competence, Single Source.

Technical challenges

Solving common design challenges by collaborating with you to engineer and manufacture customized stainless steel, alloys or PTFE hoses, bellows and artery systems.

Technical Challenges

Enabling technologies

When purity is more than a requirement

Partner with us for ultra-safe, durable hoses tailored precisely to your needs. Whether it’s leveraging our expertise or simply having a conversation with experienced professionals who understand the ins and outs of gas and liquid transportation, we’re here for you. No need to worry; we’re not your run-of-the-mill manufacturers. As the only fully integrated ODM and B2S/B2P system integrator company globally, we’re equipped to efficiently address all your gas, liquid and vacuum transportation needs. From design to manufacturing and assembly, it’s all handled in-house – no intermediaries, no hassle.

Examples of how and where our solutions are applied

Cryogenic gaslines for extreme cooling / Cryogenic gaslines in Quantum Computing

Quantum computers need to stay incredibly cold (~2 Kelvin, close to absolute zero) to function properly. At such low temperatures, molecules barely move, allowing for extreme precision at the nanometer (a billionth of a meter) scale. Because less movement means better control, this enables highly accurate operations.

To reach and maintain these temperatures requires special cryogenic gaslines that transport ultra-pure helium without contamination (e.g. moisture). Because even the tiniest impurities or moisture can disrupt the system, these gaslines must be completely leak-tight, pressure-regulated, and contamination-free.

We design and produce the cryogenic gas systems built for these extreme conditions, ensuring helium stays pure and at the right pressure. With high-quality sealing and cryo-resistant materials, CoreDux helps keep quantum computers stable and highly efficient in a field where precision is everything.

High-purity solutions for analytical instrumentation

High Tech lab equipment like mass spectrometers and electron microscopes require extreme precision and purity to work correctly. Even the tiniest gas leak can throw off results, so the fluid and gas lines must be completely sealed, made from non-reactive materials, and built to exact standards.

CoreDux provides the high-purity, leak-proof tubing designed for deep vacuum environments. Through our work, we help ensure accurate performance in pharmaceuticals, material science, and biotech research. Our reliable, contamination-free solutions help labs and industries maintain the precision they need.

Keeping medical technology safe and clean

In biotech, pharmaceuticals, and medical research, laboratory equipment must meet strict safety and cleanliness standards. This means using leak-proof, sterile tubing and materials that resist chemicals, like PTFE and PFA.

We design our custom fluid and gas transport systems to meet these tough requirements, ensuring smooth and contamination-free operation. By integrating sanitary control valves and biopharma flanges, these systems keep cleanrooms, labs, and medical devices running safely and efficiently.

With our focus on precision, purity, and compliance, we help drive innovation in the medical and pharmaceutical industries we all rely on.

Thriving under pressure

When pressure and temperature matter, there’s no room for error. That’s why our solutions are built for high-performance containment and rock-solid stability in advanced research labs and critical industries. Our systems keep processes running smoothly, maintaining exact conditions to prevent costly disruptions. With advanced purification and containment technology, we also reduce contamination risks and improve chemical safety, ensuring the highest level of reliability in places where failure simply isn’t an option.

Our knowledge

Engineer-to-engineer

The key to solving problems is viewing them from different angles. At CoreDux, we speak your language and like to share the lessons we’ve learned. Would you like to know more? Download the whitepapers below to get started.