Our two working methods

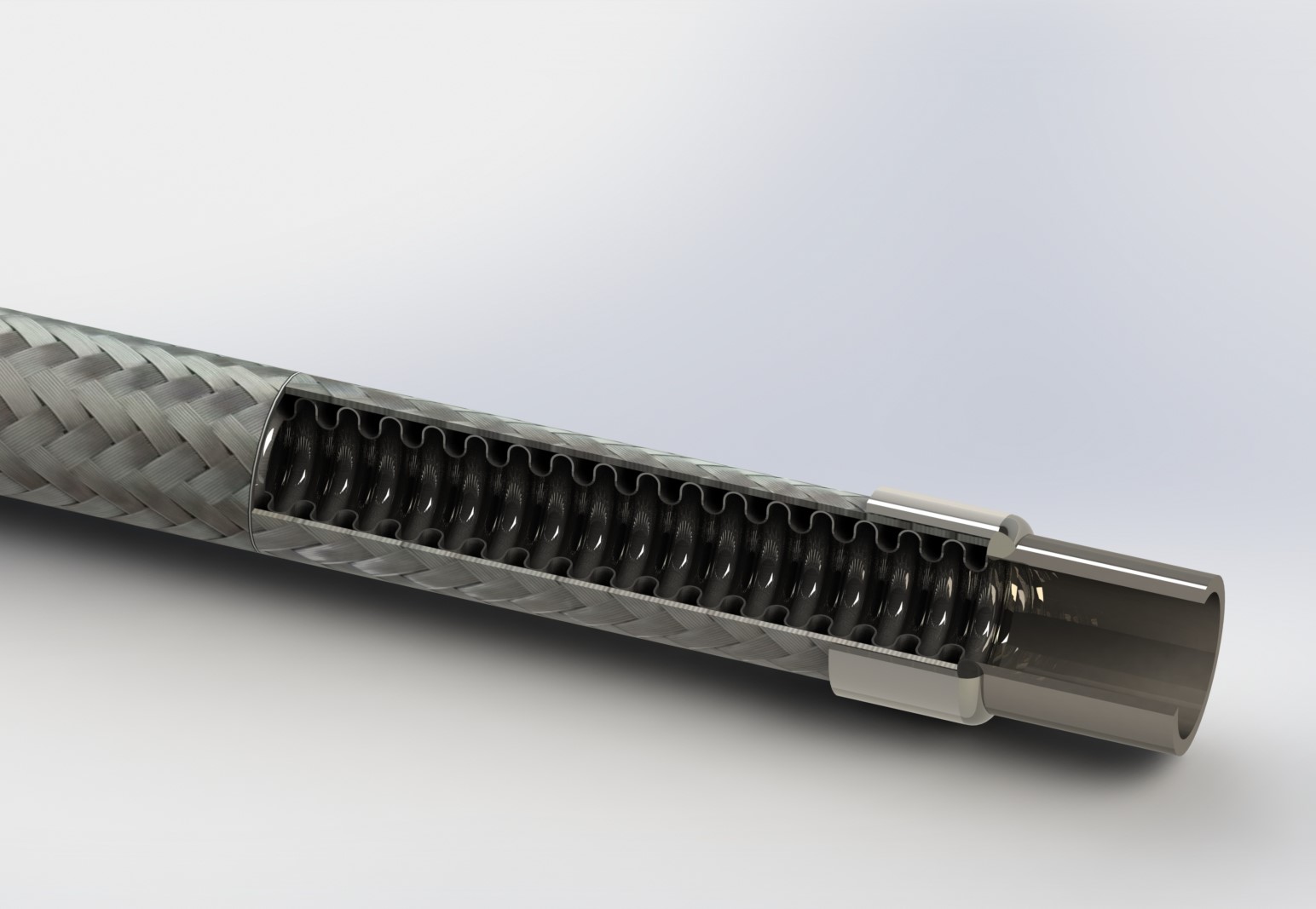

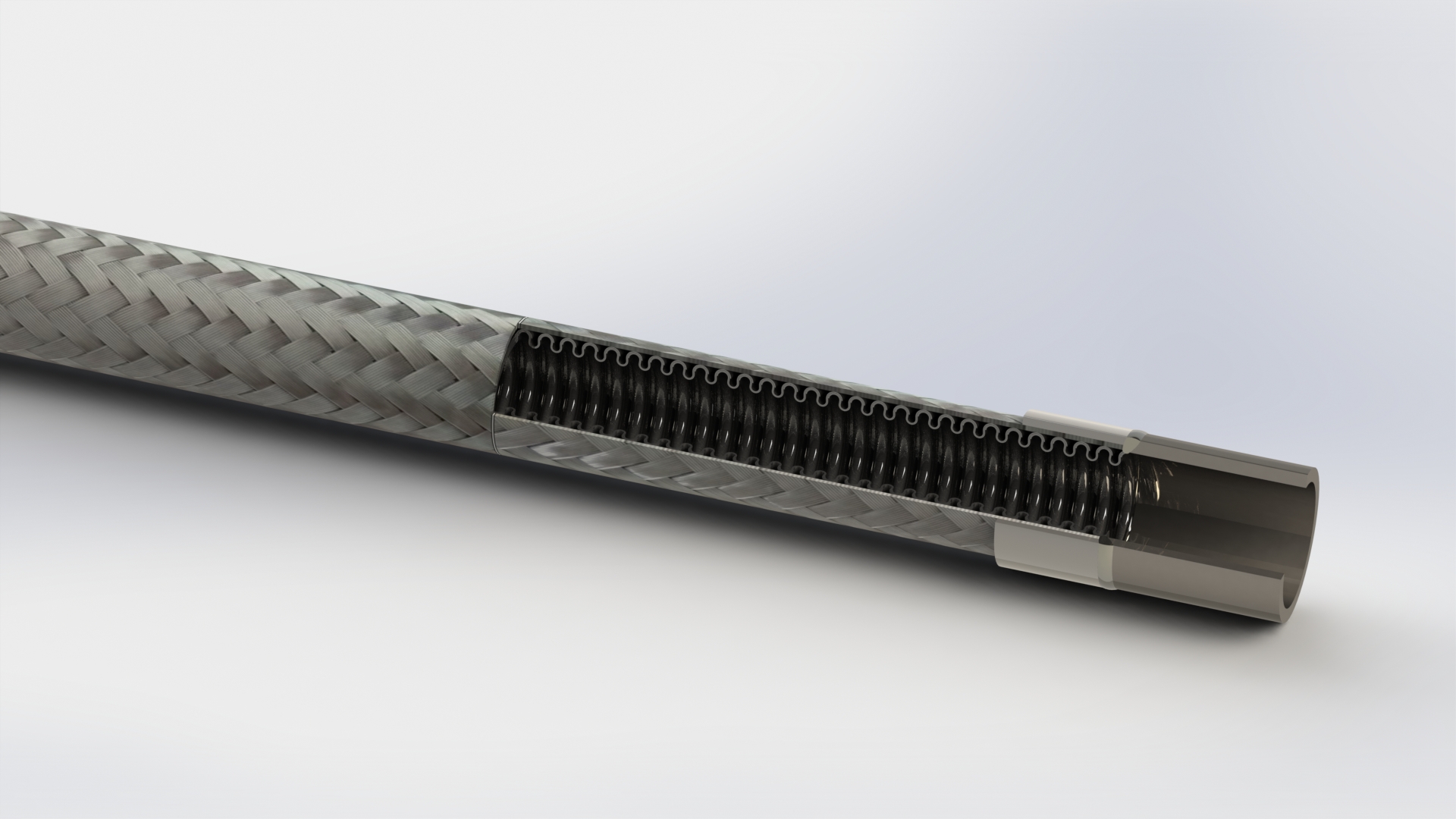

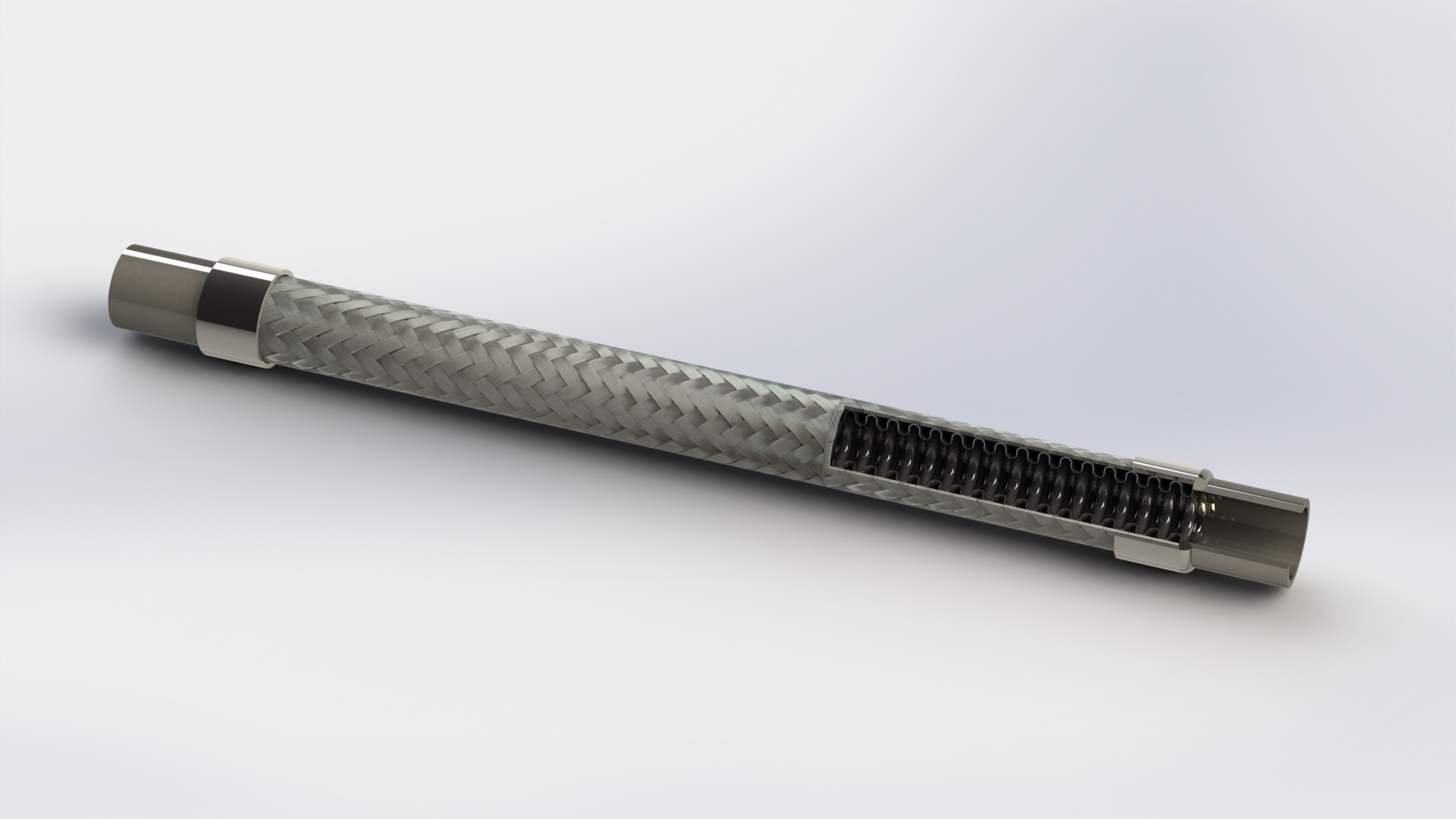

CoreDux Components

Catalog items and standardized parts that fit

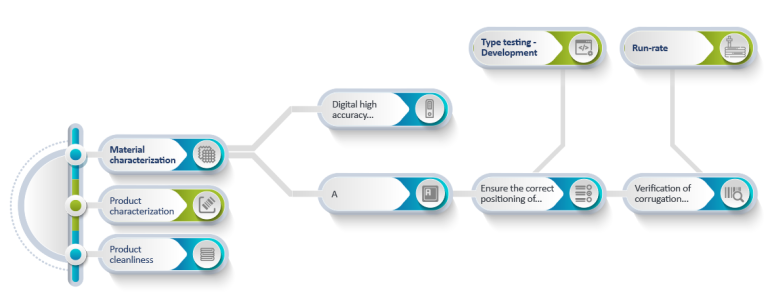

Ranging from a well-developed IP Portfolio to original equipment- and design manufacturing, We strive to be your go-to manufacturer for flexible components. As an OEM, we develop highly specific products catered to your application needs. Our product development and process roadmaps enable flawless manufacturing of tailor-made or system-specific parts.

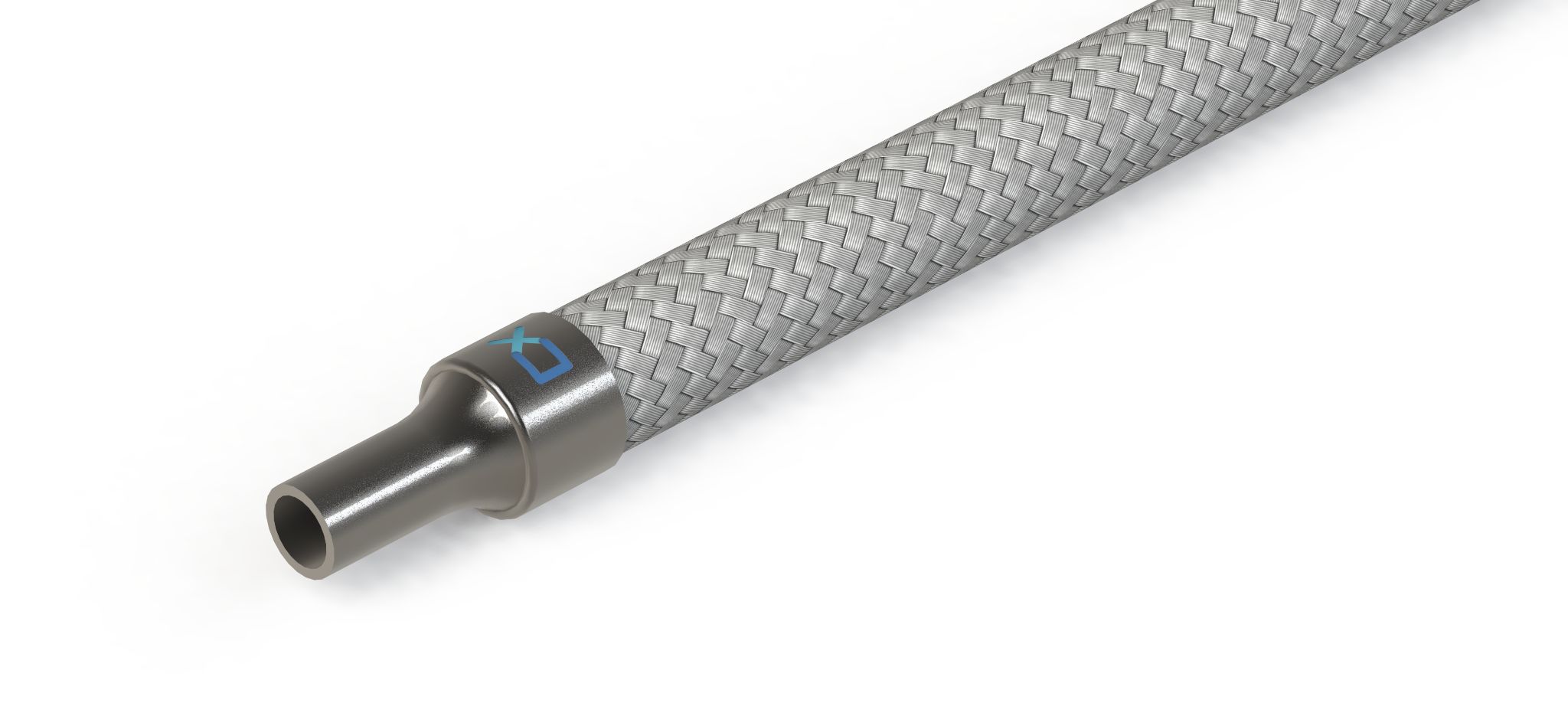

Systems Integration

From contract manufacturing to systems integration

As a built-to-print or built-to-spec manufacturer, we offer both contract manufacturing and full systems integration. This means that depending on your needs and wishes, we can provide both design and manufacturing or simply focus on the latter.