Space Industry

GAS AND LIQUID TRANSFER FOR THE FULL SPACE VALUE CHAIN Our focus ranges from rocket engines, propulsion and launchers to satellite cooling and positioning systems.

Making rockets fly

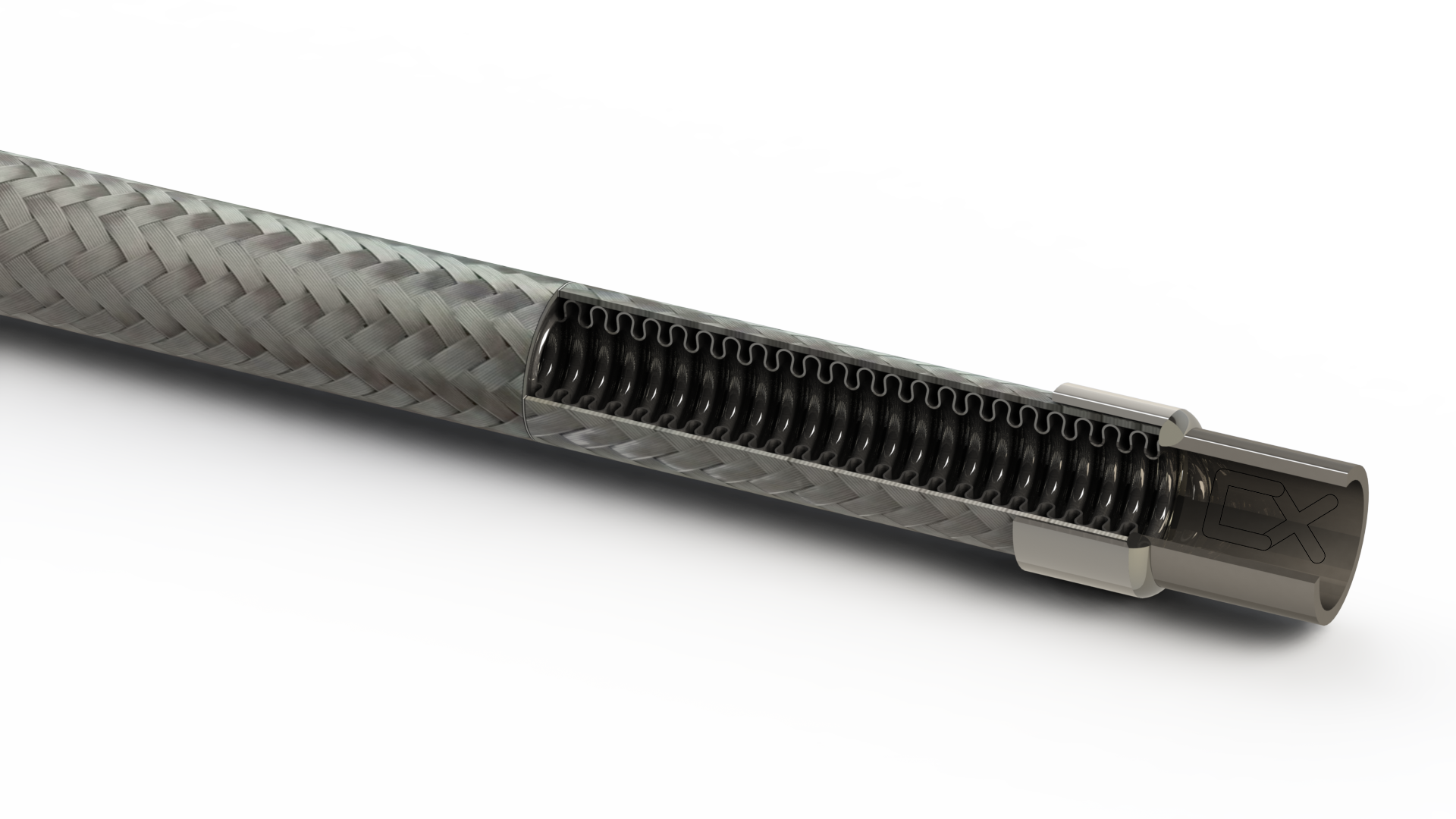

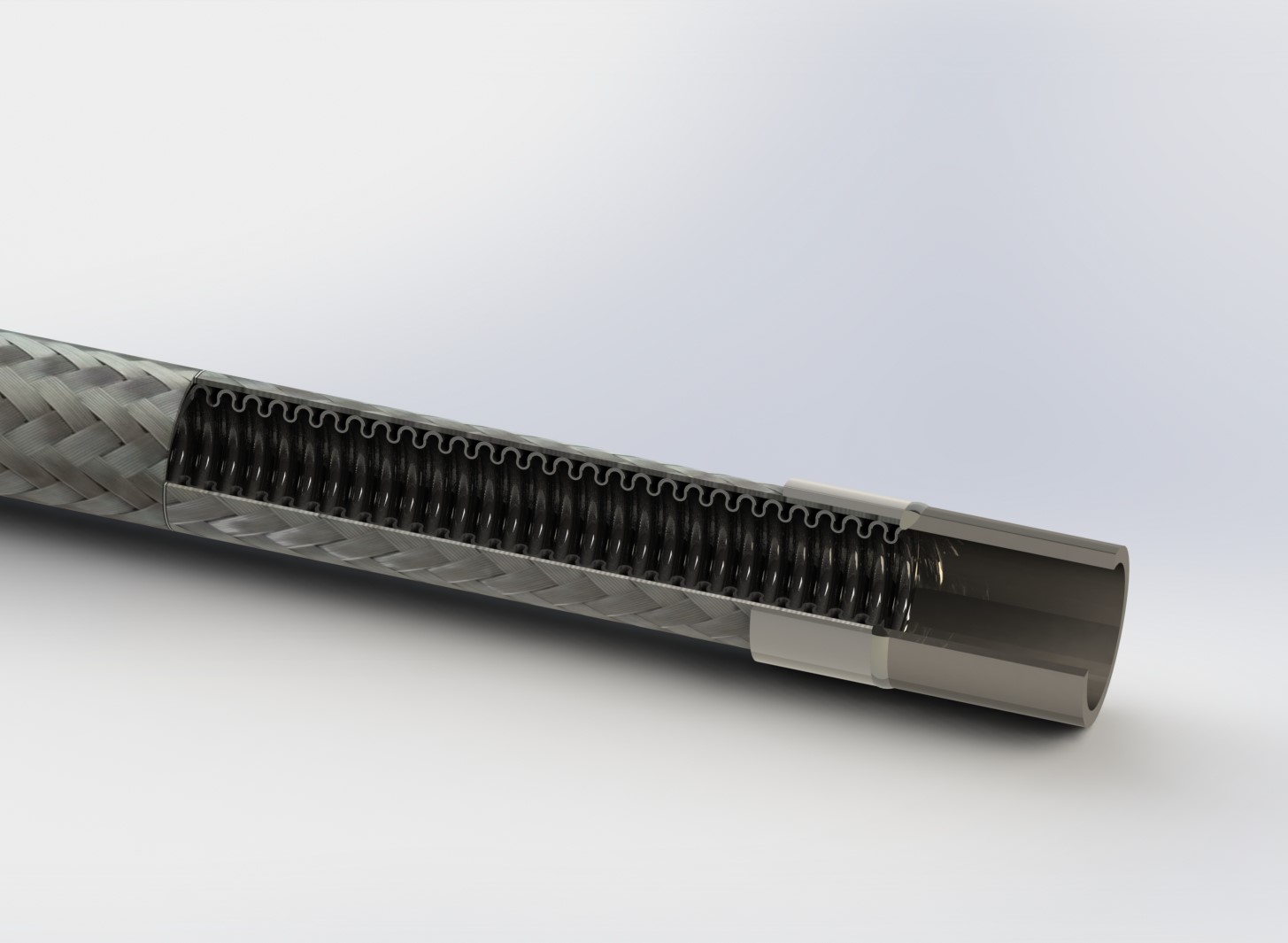

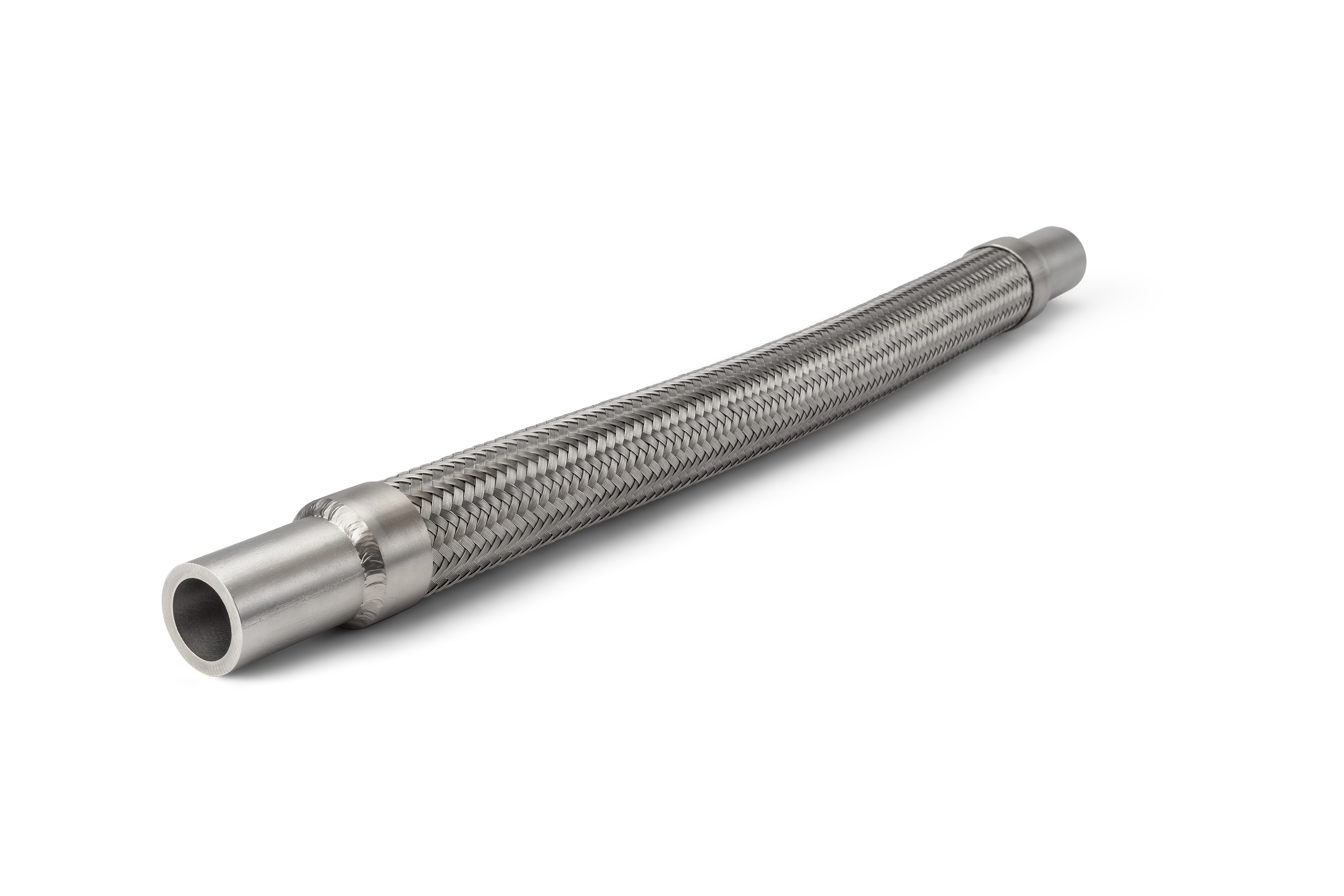

CoreDux is deeply involved in the global space industry, contributing to major launch programs and satellite missions. We develop custom hose assemblies for rocket engines, including fuel systems and cryogenic stages, and manufacture components for liquid hydrogen and nitrogen transport. Our systems are used in propulsion, satellite attitude control, and thermal regulation—where precision, durability, and fail-safety are non-negotiable.

Designed for space conditions

From vacuum to vibration, from thermal shock to mechanical load – space presents a unique mix of extreme challenges. At CoreDux, we meet these conditions with custom-engineered solutions, rigorously tested in-house. Our vacuum chamber enables qualification under space-like conditions, including cold welding, vibration testing, and thermal cycling. Whether guided by aeronautics and space standards like DO-160 or mission-specific requirements, we provide full compliance and reliability for both launch and orbit.

Co-engineering from day one

In the space industry, early-stage collaboration is essential – and often, so is technical leadership. Unlike traditional aeronautics and space, space programs frequently rely on CoreDux to define the optimal solution. We engage from the functional specification phase onward, guiding design, prototyping, and qualification. Our team takes full technical ownership to reduce iterations, improve reliability, and accelerate timelines for even the most complex systems.

I. CoreDux Components

Catalog items and standardized parts that fit

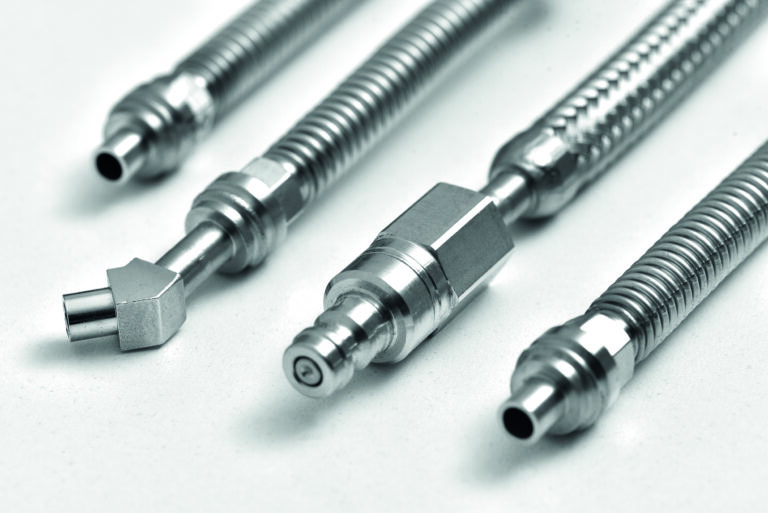

We offer a standard portfolio of standard and custom-developed flexible components, built with precision and developed in alignment with your system requirements. Our product and process roadmaps enable seamless manufacturing of application-specific parts, ranging from standalone hose assemblies to fully customized solutions.

II. Integrated solutions

From contract manufacturing to systems integration

We provide both contract manufacturing and full system integration services, whether built-to-print or built-to-spec. Depending on your project scope, we can take on detailed design and production, or simply focus on precision manufacturing.

When these come together

Dual Competence, Single Source

Our greatest value lies in combining component development and systems integration. As an original design manufacturer of our CoreDux standard portfolio and a full systems integrator, we are uniquely positioned to deliver end-to-end solutions with a single point of accountability. This is what we call Dual Competence, Single Source.

Technical challenges

Solving common design challenges by collaborating with you to engineer and manufacture customized stainless steel, alloys or PTFE hoses, bellows and artery systems.

Technical Challenges

Our focus

Precision and partnership in orbit

In space, volume may be low – but complexity is high. That’s why our focus is on tailored engineering, early collaboration, and full lifecycle support. We bring decades of know-how to co-developing cryogenic and propulsion systems, thermal regulation, and vacuum-ready solutions. Whether it’s launch vibrations or thermal extremes in orbit, we build what your mission truly needs, not just what’s on the shelf.

Our promise

Built for space, tested on Earth

At CoreDux, we go beyond supplying parts. We become a trusted partner in your mission. Our engineered artery systems are designed for extreme environments, managing cryogenic fluids, pressure, vibration, and temperature fluctuations with total reliability. Every hose assembly, every artery system is qualified and tested in-house to meet the harsh realities of space – vacuum, vibration, fatigue, and extreme temperatures. Whether aligned with DO-160 or fully customized qualification plans, we ensure every part is fit for flight, ready for orbit, and designed for long-term performance.

Our knowledge

Engineer-to-engineer

The key to solving problems is viewing them from different angles. At CoreDux, we speak your language and like to share the lessons we’ve learned. Would you like to know more? Download the whitepapers below to get started.