When hoses fail quietly: hidden risks in aerospace, new-energy & space systems

In mission-critical systems, the failure point is rarely where people expect it. It’s not always in the high tech core or the software logic. Sometimes, it’s in the most unglamorous piece of the setup: the hose.

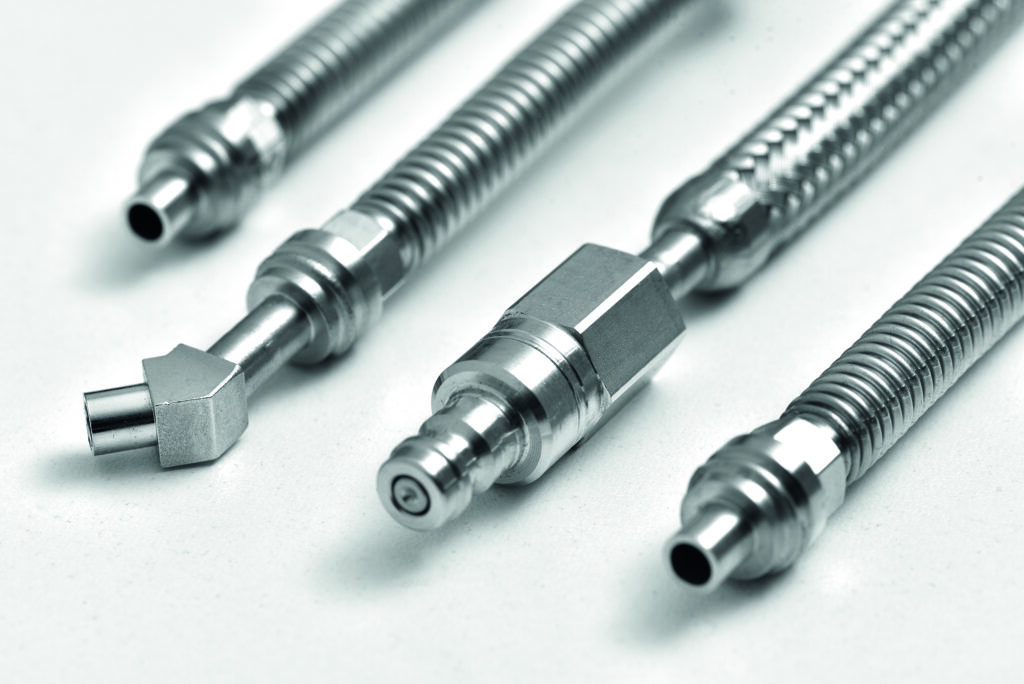

Hoses are often seen as simple connectors. Flexible. Metallic. Braided. Plug-and-play. In most industrial settings – whether you’re handling cryogenic fuels for spaceflight, corrosive gases in hydrogen plants, or cooling fluids in next-gen aircraft – hoses tend to fall into the “solved problem” category.

That is, until the problem becomes visible.

At CoreDux®, we work on making sure it never gets that far. Not by reacting to failure, but by questioning the assumptions that lead to it in the first place.

Where assumptions break down

“If you can’t see the risk, it’s easy to underestimate it,” says Max Jansen, product director at CoreDux. “But we’ve opened up enough failed hoses to know the issues are often microscopic – and always preventable.”

The danger is rarely in the pressure rating or the bend radius. It’s in the invisible: tiny weld defects, inconsistent material batches, micro-contamination, or corrosion that begins at a barely perceptible seam.

This matters because the operating environment doesn’t forgive mistakes. Hydrogen embrittlement, aggressive oxidizers, high-frequency vibrations, or fluctuating cryo-to-ambient temps all place stress on the weakest part of a system – and if that part is your hose, you’re flying blind.

Precision at the margins

Over the past year, CoreDux has introduced a new series of hose designs specifically aimed at high-risk environments. Built from C22 alloy – a nickel-rich material developed for corrosive and reactive applications – these hoses eliminate the weld seam that typically runs through standard hose construction.

“That seam is always the weak link,” Max explains. “By starting with a seamless tube and applying double-pass electropolishing on the interior, we reduce corrosion risk and improve internal cleanliness dramatically.”

These features aren’t just about extending product life. They’re about system integrity – particularly in applications where material compatibility, purity, and precision flow control are non-negotiable. Think rocket propellants. Liquid oxygen. Plasma etch gases. Nuclear decontamination loops. Fuel-cell delivery.

For these kinds of systems, CoreDux offers a modular corrosion-resistance ladder:

- Standard 316L stainless steel or Alloy 22

- Electropolished 316L or Alloy 22

- Heated and/or double-containment configurations

These aren’t off-the-shelf fixes. They’re application-specific solutions, dialed in to match both performance and safety expectations.

Supply chain isn’t always synonymous with quality

Many hose suppliers operate on a mix-and-match model: they source hose tubes from one manufacturer, fittings from another, and assemble them under their own brand. But this process often lacks consistency, especially when you’re working with corrosive chemicals or tight purity specs.

“We see cases where clients didn’t even realize they were getting mechanically formed hoses filled with grease,” Max says. “The supplier never disclosed it, and visually, the product looked identical. But over time, contamination and corrosion did their thing.”

CoreDux takes a vertically integrated approach. Hydroforming – not mechanical convoluted – is the company’s default forming method. It avoids the need for grease, ensures consistent geometry, and dramatically improves both cleanliness and fatigue resistance.

If your system is flying, freezing, or fuelling something important, this difference matters.

Resistance to change is part of the job

The hardest part about introducing a better hose? Convincing someone who hasn’t had a failure yet. “Preventing a black swan”

“We rarely get called in during a crisis,” Max says. “Usually, it’s a proactive engineer who wants to push the spec higher, reduce maintenance cycles, or rethink an old solution. But when procurement gets involved, they want numbers.”

That’s where the argument shifts from engineering to economics. If a customer replaces 800 hoses a year and CoreDux’s solution lasts 20% longer – or reduces unplanned downtime – the numbers start adding up quickly. The pitch becomes less about premium specs and more about long-term savings and system reliability.

Sometimes it’s also about enabling entirely new designs. Smaller safety factors. Tighter radii. Cleaner validation. In industries like space and energy, that flexibility opens doors.

The next layer of engineering: thermal and containment control

CoreDux is also seeing demand for next-generation configurations that go beyond corrosion resistance. This includes:

- Heated hoses for temperature-sensitive fluids and gases (preventing phase change or condensation in flight or on the pad)

- Double-containment hoses with leak-detection capabilities (especially important in facility-to-tool lines or unmanned field setups)

“We’ve started building hybrid systems – heated hoses with containment sleeves – to meet new safety specs,” Max says. “That’s where the industry is headed. If the margin of error is zero, you don’t want to improvise.”

Don’t trust the shine

A hose that looks perfect from the outside may be hiding variables no one tested for. If your system is carrying corrosive gases, reactive chemicals, or mission-critical coolants, the decision to trust a hose shouldn’t come down to appearance or a generic datasheet.

Ask what’s inside. Ask how it was formed. Ask how the weld was handled, what materials were used, and whether the inside was electropolished or just cleaned. Because the difference between a “good enough” hose and a system-grade one doesn’t show up until it’s too late.

A wake-up call for the semiconductor industry?

For many semiconductor manufacturers, gas transport systems are an afterthought. Engineers assume all hoses are the same—until they experience failures due to contamination.

CoreDux’s work in the US market has revealed a major industry blind spot. We found out that many companies unknowingly accept contamination risks because they assume their current solutions are “good enough.” Moreover, we learned that once engineers learn about our ultra-high purity capabilities, they rethink their entire approach to gas transport!

The fact that current industry standards don’t explicitly cover flexible hoses doesn’t mean they can’t be tested. At CoreDux, we’ve built our own internal testing methodology to ensure measurable, repeatable cleanliness – even in systems outside traditional validation scope.

Simply put: If you can’t validate it, you shouldn’t clean it. That’s why we make sure we can do both.

Or as one customer put it:

“I never thought a flexible hose could be this clean. We’re switching everything to CoreDux.”

Total cost of ownership: the overlooked factor

Many semiconductor manufacturers prioritize initial costs, often overlooking the long-term impact of Total Cost of Ownership (TCO). Standard hoses require multiple suppliers and cleaning steps. It’s a broken process where one company produces raw ‘industrial’ hoses, another assembles them, and yet another (attempts) cleans them before use. Each step adds cost, complexity, pollution and risk.

We eliminate these inefficiencies by delivering an ultra-clean, final product, reducing overall expenses and streamlining the supply chain. The benefits are clear: lower costs due to fewer suppliers and processing steps, better reliability through a single-source solution with full traceability, and faster maintenance with flexible hoses that minimize downtime.

“In some cases, our direct-supply model has seen a 20-30% cost benefit in comparison to existing solutions,” Eric Reijven – Senior Director, Product & Application Sales at CoreDux, adds.

A fundamental industry shift

The semiconductor industry is at a critical turning point. As chip complexity increases (with nodes shrinking to 2nm and below), contamination risks become more severe than ever. Manufacturers that continue relying on outdated gas transport systems will inevitably face increased downtime, higher defect rates, and costly contamination-related failures.

“We’re seeing more companies waking up to this reality,” says Max. “Ultra-high purity isn’t just about preventing problems; it’s about future-proofing production.”

Conclusion: A no-brainer for semiconductor manufacturers

CoreDux has disrupted the industry by proving that flexible hoses can meet the highest cleanliness standards… Something many semiconductor manufacturers didn’t think was possible! However, compared to standard piping, we deliver higher purity levels, lower costs through a fully integrated supply chain, reduced contamination risks, and minimized machine downtime.

As semiconductor technology advances, companies that prioritize ultra-high purity will gain a competitive edge, while those that don’t risk falling behind. The industry is waking up to the importance of gas transport purity, and we’re grateful to be part of this shift.

Do you want to discuss the hidden risks for your systems? Get in contact from engineer-to-engineer via our Engineer Hub here.