The silent backbone of the semiconductor industry

The semiconductor industry operates at a nanoscopic scale, where even a single particle of contamination can render a microchip useless. In an industry pushing the limits of physics, ultra-high purity isn’t a luxury, but a necessity.

Yet, while semiconductor manufacturers obsess over wafer cleanliness, gas, liquid and vacuum transportation systems – critical to these processes – are often overlooked. As a leader in ultra-high purity flexible hoses, we’d like to change this perception. By owning the entire production (value) chain, CoreDux delivers cleaner, more reliable, and more cost-effective solutions than traditional alternatives.

We sat down with our colleagues Max Jansen, Product Director at CoreDux USA, and Eric Reijven, Sr Direction, Product & Application at CoreDux Group, to dive into this brave new world of flexible ultra-high purity hoses!

Why Ultra-High purity matters in semiconductor manufacturing

Semiconductor front-end wafer manufacturing processes rely on high-purity gases such as helium, argon, hydrogen, nitrogen, and a range of other inert, reactive, or corrosive gases, whose specific chemistry is critical for key steps such as etching, deposition, and chambers cleaning

The challenge?

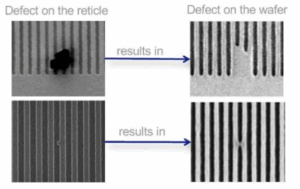

Even microscopic contaminants in these gases can cause product defects, production delays, and significant financial losses. Ultra-high purity means different things to different manufacturers. There is no universal benchmark- each customer brings their own interpretation, priorities, and tolerances based on their specific processes and risk profiles.

“People don’t realize how much damage a tiny impurity can cause,” says Max. “When we’re talking about 1 and 2nm chips, a single contaminant can ruin an entire batch.”

A single contamination event can have serious consequences. It lowers production yields by causing defects in chips before they even reach consumers. It also drives up costs, as contamination may lead to production shutdowns, wasting expensive raw materials. Additionally, gas impurities can cause equipment failures, leading to longer downtime and disrupting production timelines.

Why standard gas transport solutions aren’t good enough

Traditionally, the semiconductor industry has relied on rigid stainless steel piping with electropolished inner surfaces to transport high-purity gases. These systems are standardized and widely accepted; but not necessarily the best solution.

“Rigid piping has been the industry standard for so long that many manufacturers don’t even question it,” says Eric. “But when you take a closer look, the drawbacks become obvious.”

Rigid piping comes with several limitations. First of all: maintenance is challenging since once installed, cleaning or modifications become cumbersome. Fixed pipes also pose misalignment risks, as they don’t easily adapt to design changes or machine expansions. Additionally, every weld, joint, and bend creates a potential contamination hotspot, increasing the risk of impurities in the system.

Even within industry guidelines such as SEMI F19/F20, the focus is primarily on flat, metallic surfaces – making little to no mention of (corrugated flexible hoses and bellows. This has led many engineers to assume that flex systems can’t be cleaned and validated to the same standard of purity.

Our answer to this challenge? Flexible high-purity hoses – a solution that wasn’t even considered viable by many semiconductor manufacturers until recently.

A disruptive shift: high-purity flexible hoses

Not to toot our own horn, but CoreDux is at the forefront of this paradigm shift. We’re challenging the long-standing assumption that only rigid pipes can achieve ultra-high purity. The industry is now discovering that our flexible hoses not only meet, but even exceed, the purity standards of traditional piping.

“People assume flexible hoses are a compromise,” says Eric. “But in reality, they’re the better option in particular use cases.

What makes CoreDux different?

Unlike competitors who purchase pre-made hoses and assemble them, CoreDux owns the entire value chain; from raw (base) material to final assembled product. Second, we challenge the idea that only rigid, flat-smooth surfaces can meet ultra-high purity standards and are able to be correctly validated according to existing SEMI and ISO norms.

While traditional benchmarks may overlook flexible hoses, we’ve developed proprietary production and validation protocols that prove otherwise. Finally, our vertical integration ensures purity is maintained at every step rather than treated as an afterthought. This method brings two major advantages:

- Proactive purity, not reactive cleaning

Most hose manufacturers assemble pre-made parts and then try to clean the finished product. CoreDux, on the other hand, designs every step of its production process to maintain purity from the start – preventing contamination rather than fixing it afterward. The result is a product that’s much less prone to contamination.

- Molecular-level cleanliness

Competitors often focus on particle contamination, but CoreDux takes cleanliness to the molecular level. This is especially crucial for semiconductor manufacturers that rely on chemical precision, such as atomic layer deposition (ALD) and etching processes.

Beyond Dutch standards

Our technology evolved alongside a renowned Dutch and German leader in lithography capital equipment, setting our standards to meet their strict cleanliness requirements. But when we entered the US market, we discovered something surprising:

“Many American semiconductor companies didn’t even know this level of cleanliness was possible in flexible hoses,” says Max.

CoreDux’s hoses were often cleaner than necessary, but once customers understood the risks of contamination, they wanted the cleanest solution available.

A Wake-up call for the semiconductor industry?

For many semiconductor manufacturers, gas transport systems are an afterthought. Engineers assume all hoses are the same—until they experience failures due to contamination.

CoreDux’s work in the US market has revealed a major industry blind spot. We found out that many companies unknowingly accept contamination risks because they assume their current solutions are “good enough.” Moreover, we learned that once engineers learn about our ultra-high purity capabilities, they rethink their entire approach to gas transport!

The fact that current industry standards don’t explicitly cover flexible hoses doesn’t mean they can’t be tested. At CoreDux, we’ve built our own internal testing methodology to ensure measurable, repeatable cleanliness – even in systems outside traditional validation scope.

Simply put: If you can’t validate it, you shouldn’t clean it. That’s why we make sure we can do both.

Or as one customer put it:

“I never thought a flexible hose could be this clean. We’re switching everything to CoreDux.”

Total cost of ownership: the overlooked factor

Many semiconductor manufacturers prioritize initial costs, often overlooking the long-term impact of Total Cost of Ownership (TCO). Standard hoses require multiple suppliers and cleaning steps. It’s a broken process where one company produces raw hoses, another assembles them, and yet another cleans them before use. Each step adds cost, complexity, pollution and risk.

We eliminate these inefficiencies by delivering an ultra-clean, final product, reducing overall expenses and streamlining the supply chain. The benefits are clear: lower costs due to fewer suppliers and processing steps, better reliability through a single-source solution with full traceability, and faster maintenance with flexible hoses that minimize downtime.

“In some cases, our direct-supply model has seen a 20-30% cost benefit in comparison to existing solutions,” Eric adds.

A fundamental industry shift

The semiconductor industry is at a critical turning point. As chip complexity increases (with nodes shrinking to 2nm and below), contamination risks become more severe than ever. Manufacturers that continue relying on outdated gas transport systems will inevitably face increased downtime, higher defect rates, and costly contamination-related failures.

“We’re seeing more companies waking up to this reality,” says Max. “Ultra-high purity isn’t just about preventing problems; it’s about future-proofing production.”

Conclusion: A no-brainer for semiconductor manufacturers

CoreDux has disrupted the industry by proving that flexible hoses can meet the highest cleanliness standards… Something many semiconductor manufacturers didn’t think was possible! However, compared to standard piping, we deliver higher purity levels, lower costs through a fully integrated supply chain, reduced contamination risks, and minimized machine downtime.

As semiconductor technology advances, companies that prioritize ultra-high purity will gain a competitive edge, while those that don’t risk falling behind. The industry is waking up to the importance of gas transport purity, and we’re grateful to be part of this shift.