Why cleanliness is mission-critical in modern wafer manufacturing

As chip designs get smaller and more complex, and the risks get bigger. In the semiconductor industry, everything is trending towards more: more functionality, more performance, more complexity.

But ironically, the margin for error is getting smaller with every generation.

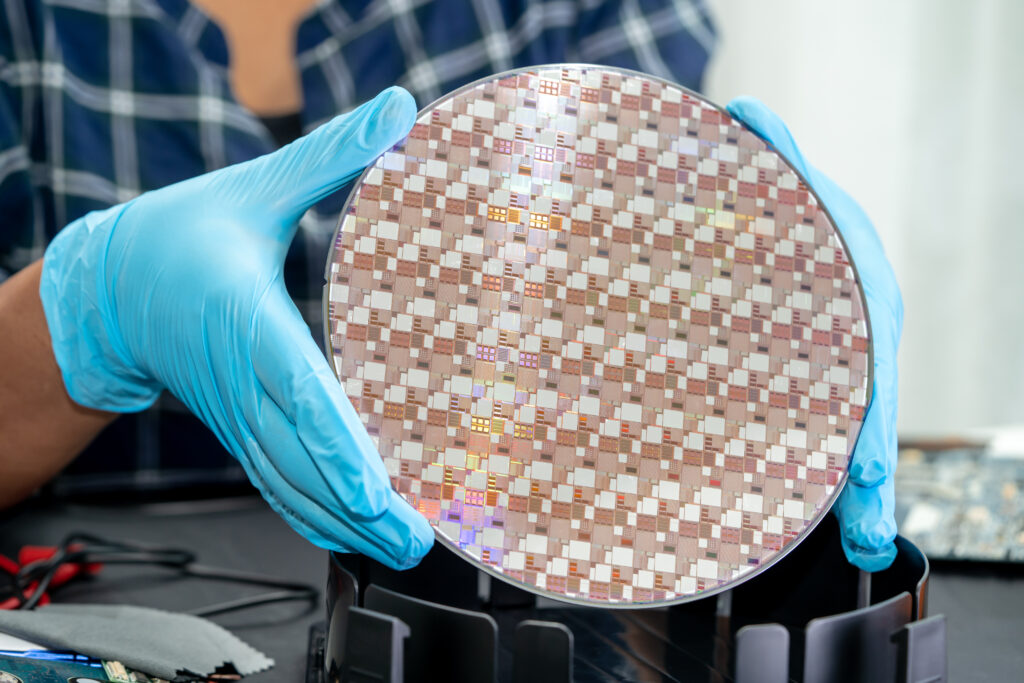

A single particle, undetectable to the human eye, can compromise an entire wafer. That wafer might contain up to 10,000 individual microchips. If one of those chips has a defect caused by a microscopic particle or chemical impurity, the entire wafer might be scrapped. That’s thousands of chips, gone. Add up the cost of materials, time, and wasted energy, and you’re looking at serious money.

Cleanliness isn’t just a technical issue. It’s a business imperative.

This is why purity matters more than ever.

Introduction

Wafer contamination is one of those problems that doesn’t make headlines but quietly chips away at yield, profitability, and trust. It doesn’t matter how cutting-edge your lithography, deposition or chip manufacturing machine is if contamination creeps in through a hose, valve, or connector.

This article takes a practical look at the hidden danger of contamination in semiconductor front-end wafer manufacturing. We’ll explore how it happens, why it’s so hard to detect, and what companies are doing to stay a step ahead; including lessons learned from decades of providing ultra-clean parts for a leading Dutch semiconductor manufacturer.

The shrinking margin for error

There was a time when semiconductor contamination was a manageable nuisance. Today, it’s an existential risk to your production line. Moore’s Law has driven rapid miniaturization. Chips are smaller, denser, and packed with more functionality than ever before. But there’s a tradeoff: the smaller the chip, the more vulnerable it becomes to microscopic contaminants.

Wafer production isn’t just sensitive, it’s unforgiving. In this environment, “first-time-right” manufacturing is more than an ideal. It’s survival. The industry is shifting from detecting contamination to avoiding it entirely. In today’s fabrication plants, it isn’t just about keeping the cleanroom clean. Every part of the production environment must meet higher standards; from the lithography, defectivity and deposition tools to the hoses and pipes carrying gases and liquids (that’s where we come in).

After all, a system is only as clean as its dirtiest link….

What is wafer contamination?

To understand why prevention is key, we first need to understand what contamination actually looks like.

Contamination in semiconductor manufacturing comes in many forms: particles, molecular, chemical impurities, moisture, or corrosion. It can enter the process through something as basic as the piping system that transports gases or liquids.

Imagine painting a detailed mural with a dirty brush. You don’t see the flaw until it’s already baked into the final product. That’s what contamination is like in chip production; you only find out when it’s too late to fix it.

Contaminants can come from unexpected sources: seals that shed particles, metal ions from corroded pipes, or organic compounds from a poorly cleaned hose. Once introduced, they can interfere with lithography patterns, etching precision, or deposition layers. And because contamination is often microscopic, it slips past the eye until yield numbers start to drop.

The cost of contamination

Contamination doesn’t just mean lower yield. It can lead to chip failures, delays, and expensive troubleshooting. Even if issues are caught during in-process metrology, repair takes time and money – and it’s not always possible. FAB’s want “first-time-right” results because that’s what keeps costs predictable and products moving forward in the FAB.

The problem is that in a multi-step process (some with up to 100 cycles per wafer), a small failure early on can cascade. That means added value is destroyed before it can be recovered.

Why tracing contamination is so difficult

Here’s the catch: even when contamination is found, it’s incredibly hard to pinpoint the source. In theory, chipmakers can detect issues through yield analysis or inspection tools. In practice, there are so many variables that tracing a specific impurity back to a hose, filter, or connection point is nearly impossible.

That’s why manufacturers are risk-averse by default. If they find a cleaner, safer component, they switch – not because they know it’ll solve the problem, but because they can’t afford to find out the hard way. Prevention is the only rational strategy.

That is why modern fabrication plants have moved from reactive to preventive strategies.

Preventing over curing

Metrology, filtration, and constant monitoring are all designed to catch contamination early. But ideally, contaminants never enter the system in the first place. That means looking hard at every element of the infrastructure – including hoses, pipes, joints, and fittings.

As we’re approaching the mid-twentieth-first century, a hose or pipe that sheds particles or holds residual chemicals is simply no longer acceptable.

Filters, fail-safes, and first-time-right thinking

Contamination control in modern fabs is not a single line of defense; it’s a layered system.

Cleanrooms, inspection tools, real-time monitoring, and filtration all work together to keep impurities out of the production process. But even the best filter is only the final safeguard. If components further upstream are shedding particles or leaching chemicals, contamination still enters the system, just earlier in the chain.

Filters function like insurance policies. They are essential, but ultimately reactive. A clogged filter can reduce pressure, trigger alarms, and lead to unplanned downtime. When contamination reaches filters too frequently, it drives up maintenance and replacement costs.

This is why forward-thinking fabs are changing their approach. Instead of relying on filters to catch impurities, they are investing in cleaner, more stable infrastructure that prevents contamination at the source. It is a “first-time-right” philosophy: design systems that stay clean, so they don’t need constant correction.

Why delivery systems matter too

For years, the focus of contamination control has been on cleanroom environments. But what happens before gases and liquids reach the cleanroom? Contamination can begin much earlier, inside the delivery systems that move critical materials throughout the facility.

Hoses, pipes, fittings, and joints are often overlooked, even though they are essential to process integrity. If a hose isn’t properly cleaned, or if materials degrade under heat or chemical exposure, they can release particles or compounds into the production flow.

That is why the definition of a clean environment is expanding. More fabs are extending contamination control beyond the cleanroom floor into the sig & sub-fab, where infrastructure and utility systems live. The principle is simple: if your facility gas delivery systems aren’t clean, your wafers won’t be either.

A quiet revolution in materials

In this context, some manufacturers are beginning to recognize that in specific situations, flexible hoses can offer advantages over traditional rigid piping. While pipes remain the standard in most FAB applications, hoses are increasingly being used where they help minimize contamination, extend filter life, reduce downtime, or improve yield. These adjustments may seem minor, but they can make a significant impact in targeted use cases.

And in a high-stakes industry where uptime is everything, those small improvements add up.

Beyond clean: a systemic evolution

For more than two decades, CoreDux has worked behind the scenes with some of the world’s most demanding manufacturers. Our clients include a leading Dutch lithography OEM´s and a German leader in optical and imaging technology. The required level of trust wasn’t earned overnight. It came from years of evolving alongside our clients’ needs both in technology and in mindset.

The journey started with rigid stainless-steel pipes, transitioning into stainless-steel hoses for vacuum applications. These worked well, but were slow to install and difficult to maintain. Over time, CoreDux introduced ultra-clean, flexible hose systems that met or exceeded cleanliness standards, without sacrificing durability or pressure rating.

This wasn’t just a product shift. It was a mindset change. Flexible hoses reduced maintenance downtime and opened up new design possibilities. In high-stakes environments where every hour of uptime counts, that’s not a luxury, it’s a competitive edge.

Today, we are taking that experience beyond machines. In partnership with system integrators, we’re now supplying full-facility gas distribution lines for entire fabs.

It’s like moving from clean instruments to clean infrastructure.

The road ahead: clean systems for complex FAB’s

Wafer production is moving fast. So are the facilities that support it. Mega-fabs like those being built by one of our American clients require infrastructure on a different scale. Gas and fluid systems must now cover entire buildings, not just machines.

This is where we see our next frontier. The same ultra-clean, flexible hose technology that worked inside machines is now powering full fab distribution systems. And with the rise of cooling-heavy processes, PTFE clean hoses are gaining traction, while SS ultra-clean hoses are proving essential for precise gas delivery. We’re not just making hoses, we’re helping define what “clean” means at every level of the semiconductor supply chain.

Closing thoughts: clean is the new smart

Cleanliness isn’t a nice-to-have. It’s a performance driver. As the semiconductor industry pushes the limits of scale, density, and efficiency, the role of purity becomes more central.

Preventing contamination before it starts (through smarter materials, better infrastructure, and consistent cleanliness standards) is one of the most cost-effective ways to ensure higher yield and lower risk.

After all, in semiconductor manufacturing, you can’t fix what you can’t see. That makes prevention the smartest play in the book.

Wafer contamination might not be flashy, but it can be fatal to your bottom line. Cleaner systems, smarter materials, and better design aren’t just technical upgrades; they’re business strategies.

Whether it’s a $100 hose or a $10 million cleanroom, every detail matters. And companies that treat cleanliness as a core competency, not an afterthought, will have the edge in the chip race.

Cleanliness is no longer optional. It’s fundamental. And it starts with every component, every connection, every step.

Do you want to discuss your challenges in wafer manufacturing from engineer-to-engineer? Let our engineers now via the Engineer Hub!