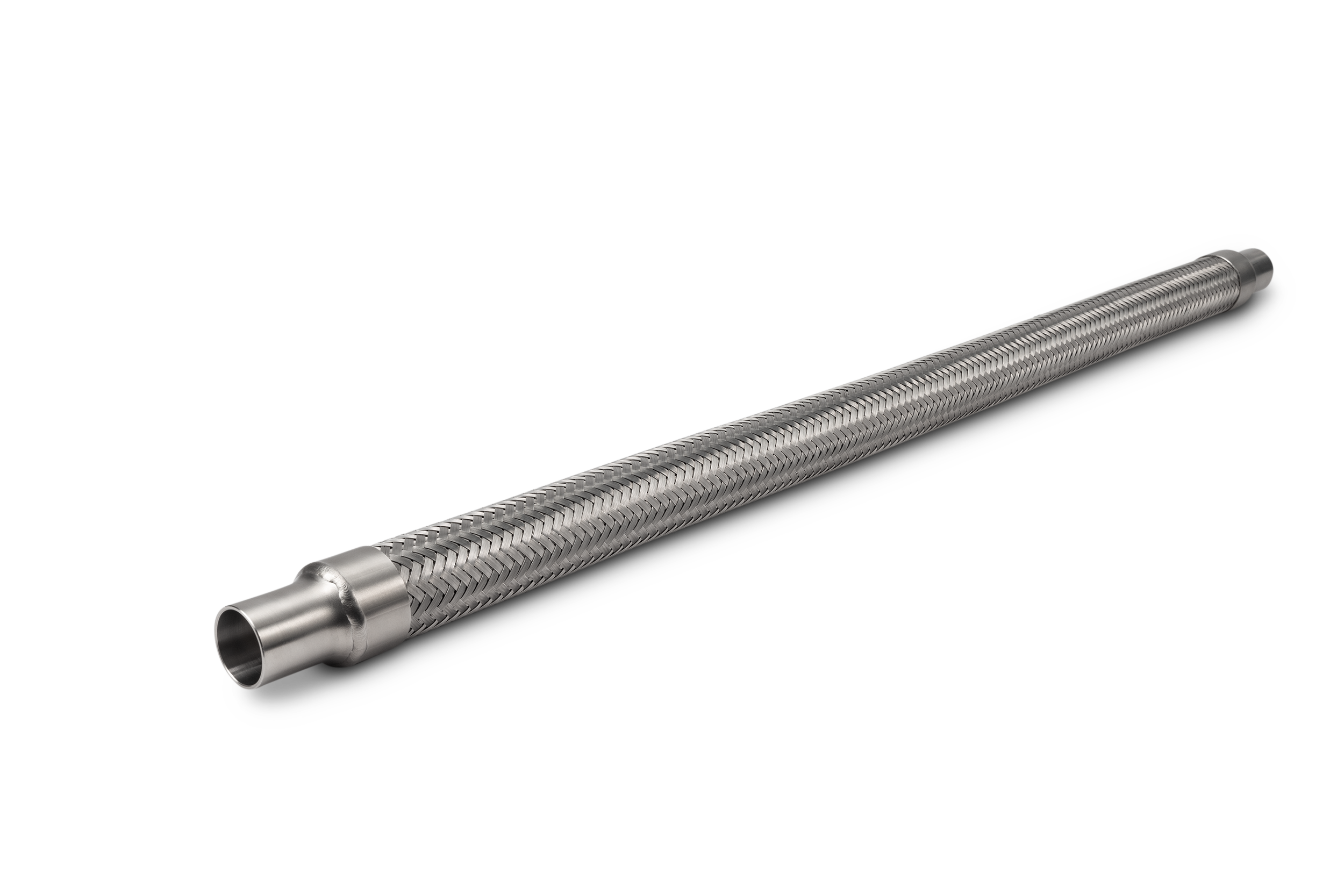

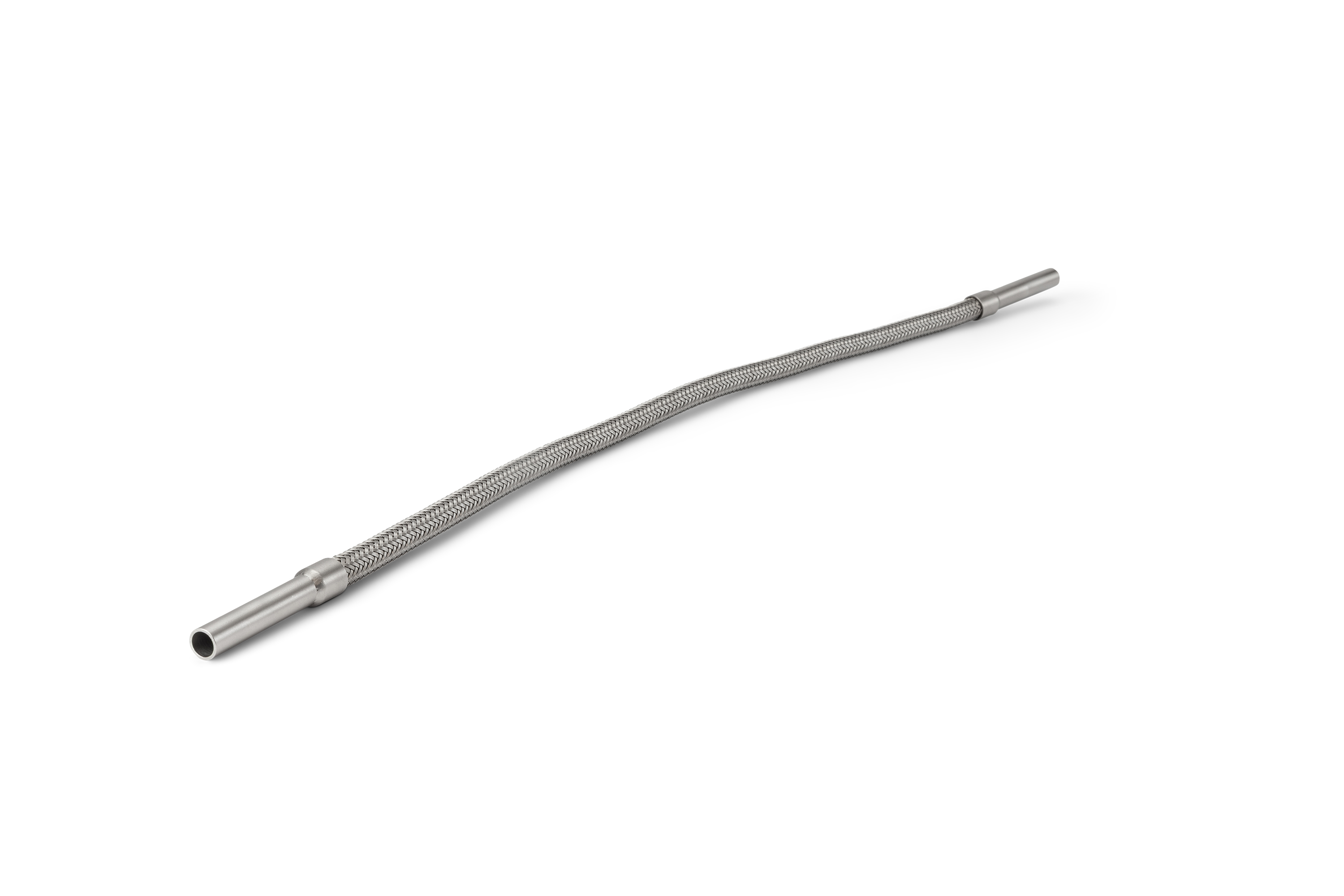

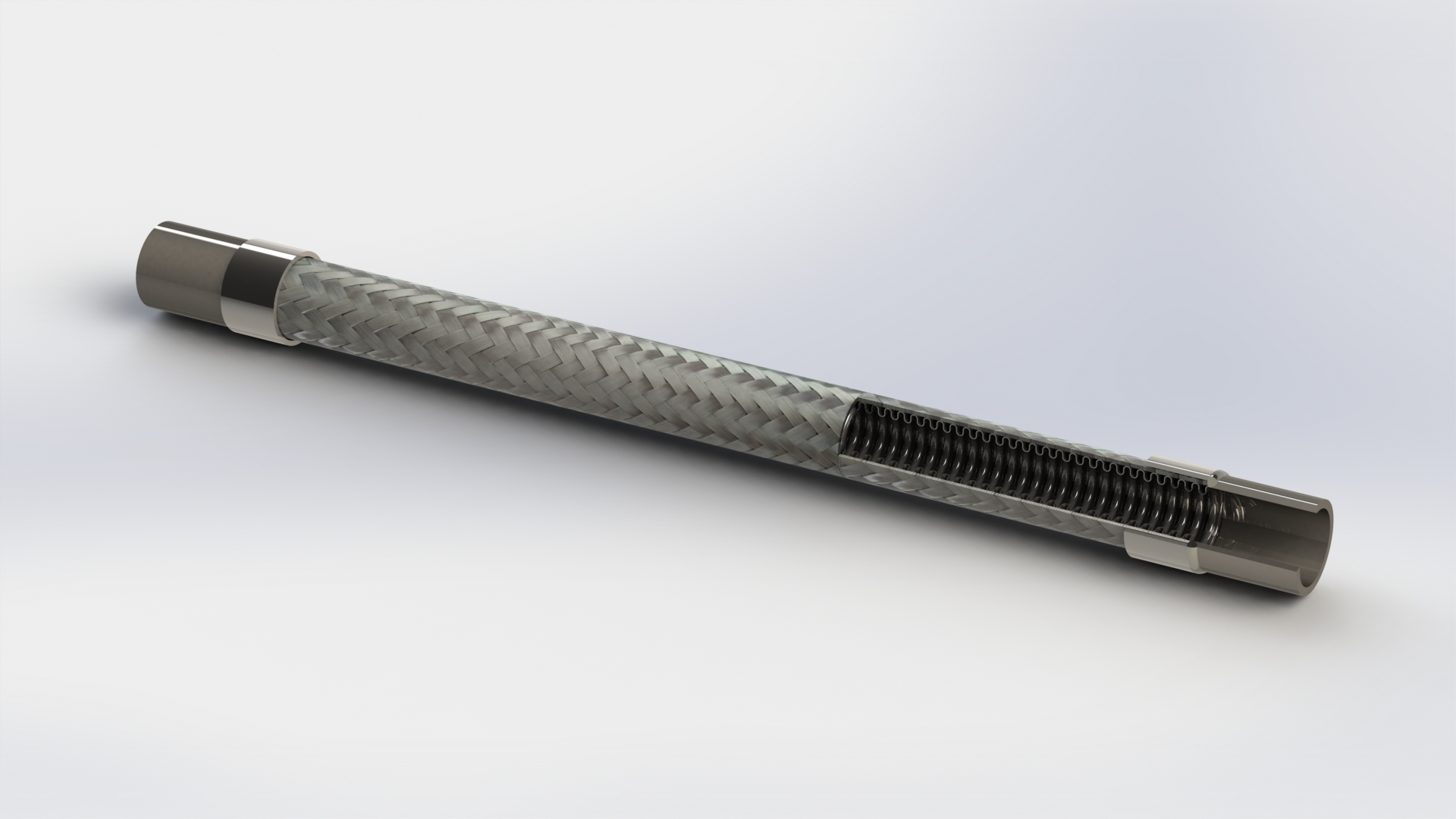

Looking for high-temperature tubing that can withstand up to 500 degrees or more? Or nitrogen pipe freezing? No problem, we can help you – whether its nuclear fusion with helium cooling transport (cryogenic) lines in aerospace and semicon, vacuum lines in high-tech or warming up magnets in life sciences. We are experts in this field and know exactly how to find the right solution for your challenge. We understand changes in temperature can affect the material structure, flexibility, characteristics and performance of a hose. It is therefore essential to engineer a hose or hose assembly that is able to combat all this.

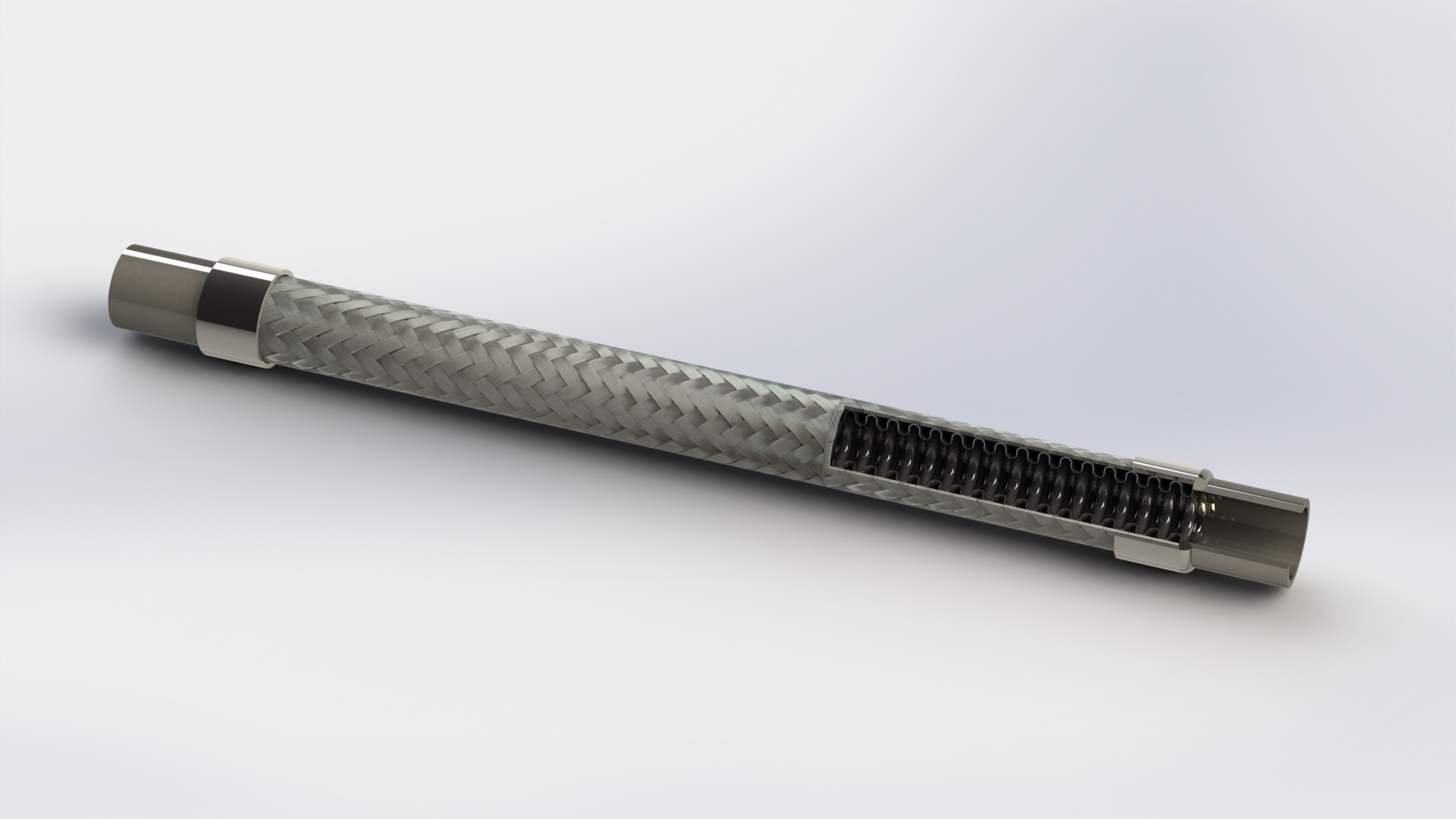

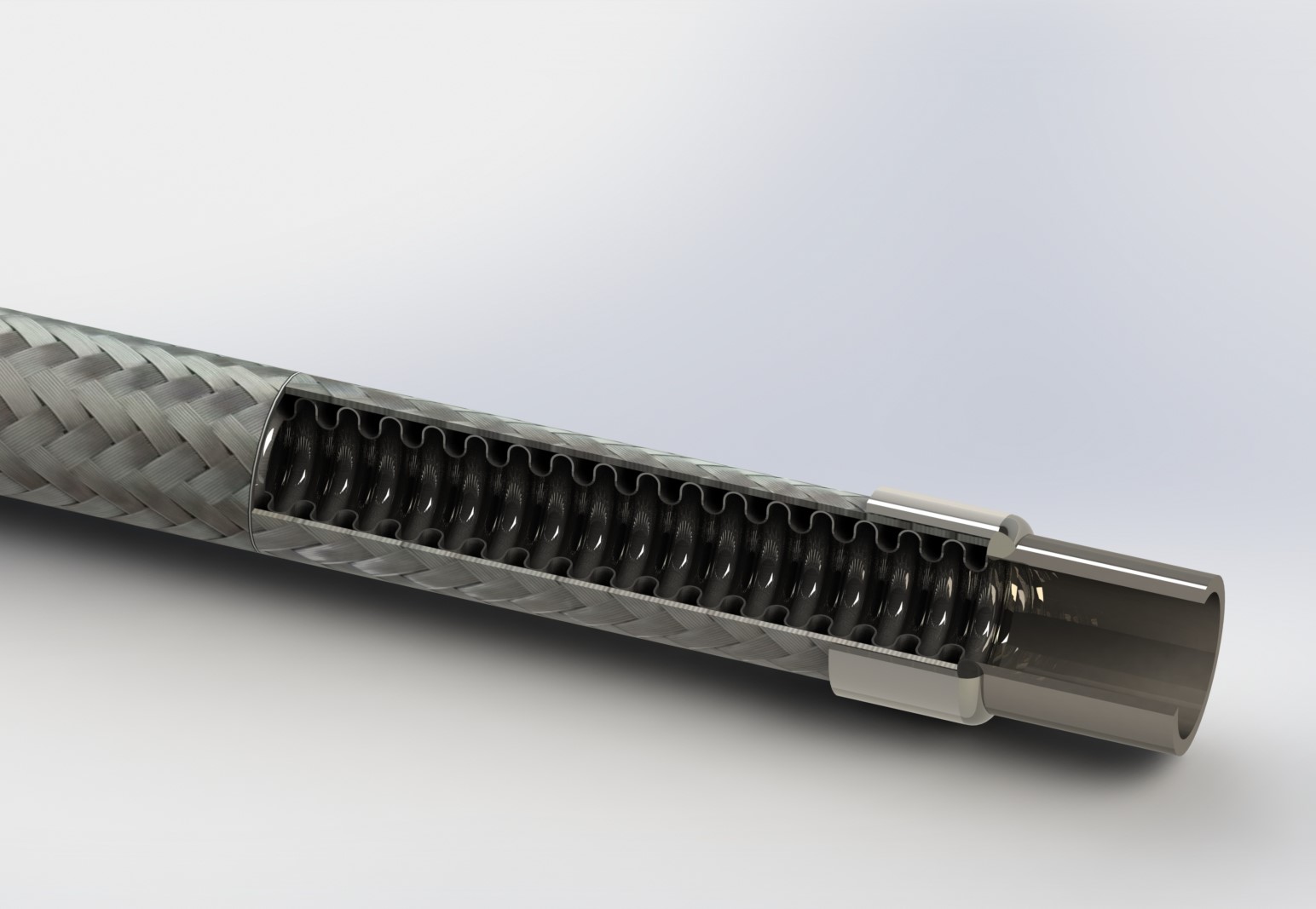

The transportation of extremely hot liquid or freezing cold liquid needs to be safe, precise, fully effective and cost-effective. It is therefore essential to have a robust metal hose that always maintains the same temperature inside the hose and also keeps the external temperature out. This challenge often comes in combination with other challenges such as relative movement, leak-tightness and vibration. At CoreDux, we take everything into account.