How can we help you?

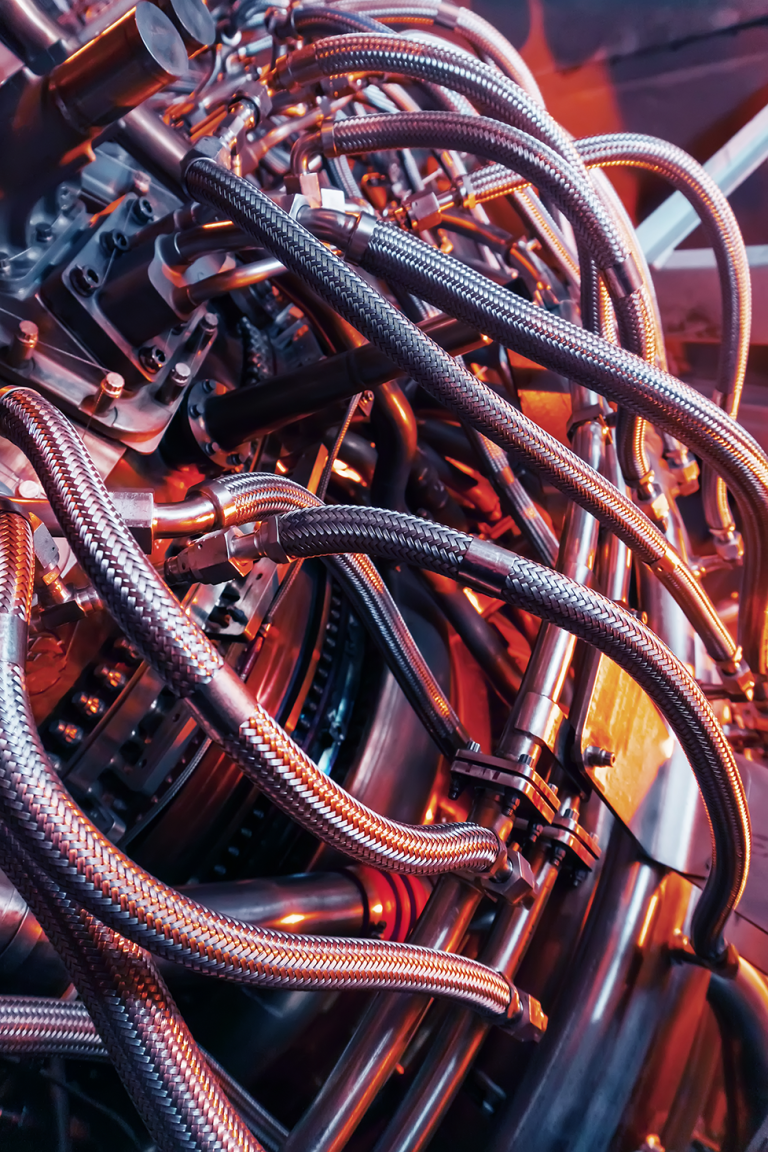

Talk with our experienced engineering experts to find the right solutions for the complex challenges you face in gas and liquid transportation. Rest assured in knowing that we are the only full-service ODM and B2P company in the world that can solve all your liquid and gas transportation challenges in a single go. We design, manufacture, and assemble everything in-house without third parties involved.

Would you like to find out more?