Mamba L

Mamba L

With our products we ensure you of

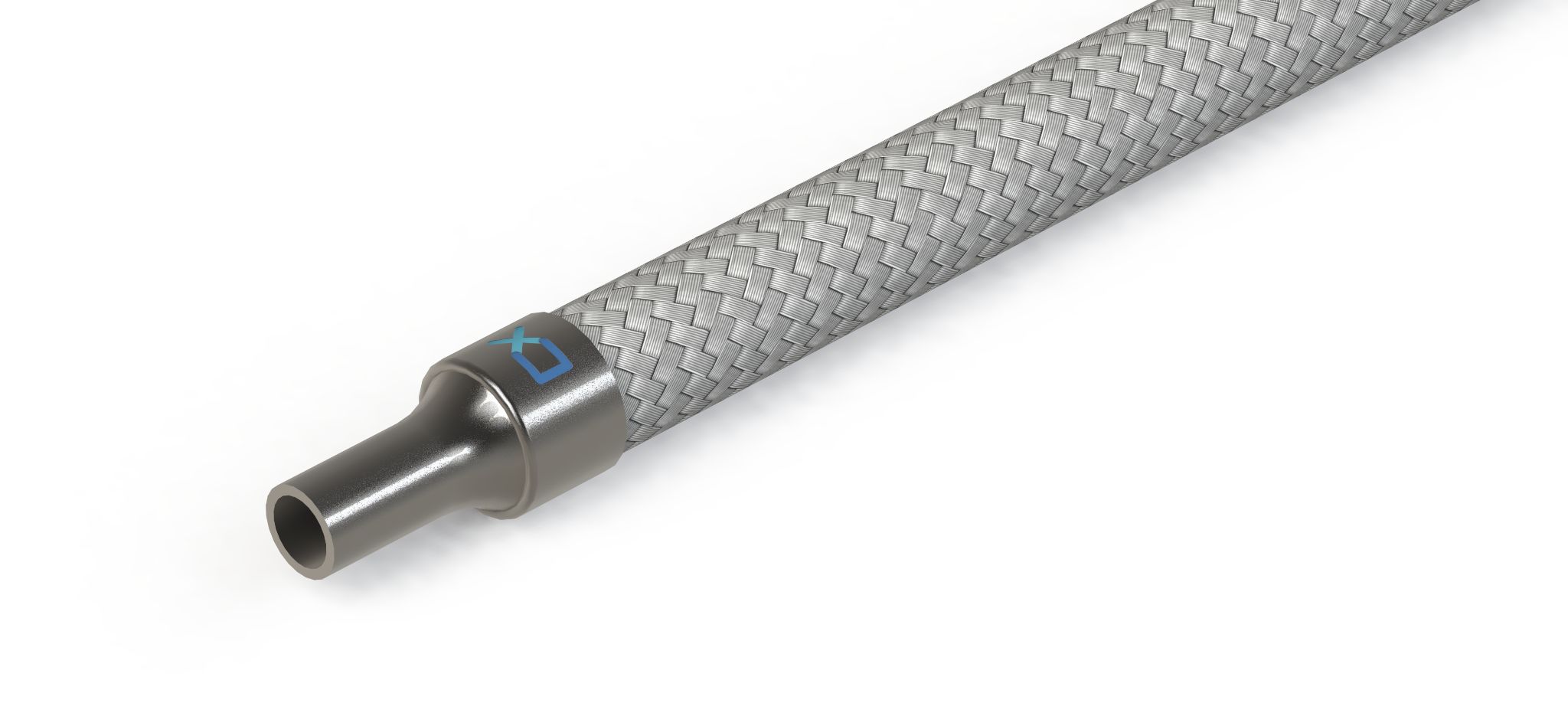

Standard EN ISO 1.4404 I AISI 316L (other grades available)

Compliant standards: EN ISO 10380, EN ISO 9001

Clean manufacturing process

Diameter [DN]

6

10

12

20

25

Diameter [inch]

1/4"

3/8"

1/2"

3/4"

1"

Stub outside diameter [mm]

6.35

9.53

12.7

19.05

25.4

Stub wall thickness [mm]

0.89

0.89

1.24

1.24

1.65

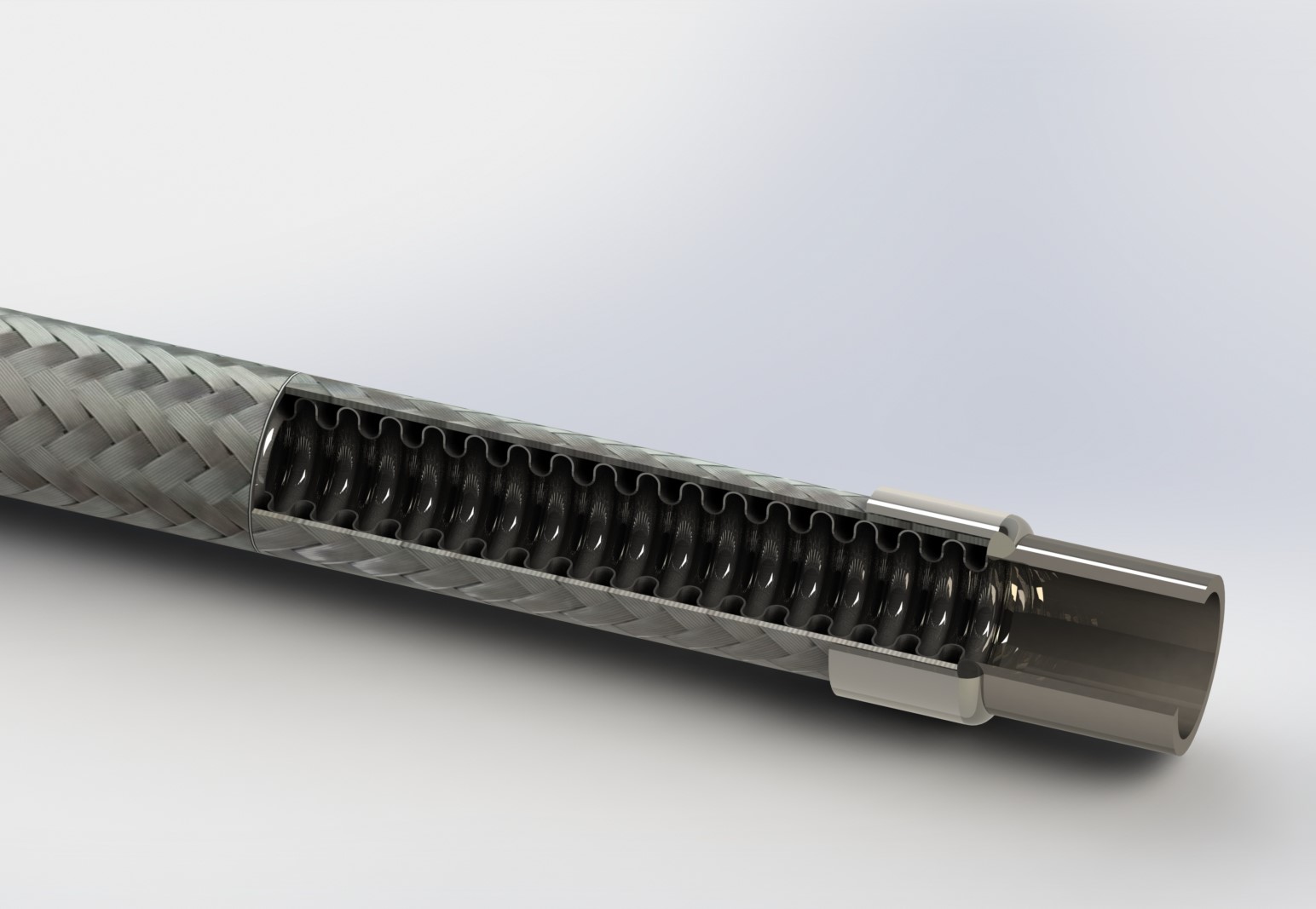

Hose inner diameter [mm]

6

10.1

12.4

19.9

24.9

Hose outside diameter [mm]

11.4

17.8

20.2

29.9

36.4

Static bend radius [mm]

20

20

39

38

45

Dynamic bend radius [mm]

110

102

165

163

180

Max. allowable pressure at 20 °C [bar]

Burst pressure at 20 °C [bar]

Compliance

- EN ISO 9001

- EN ISO 10380 / ASME 31.3

Cleanliness

- Standard deliveries: White room

- Vacuum, Ultra high purity: possible upon request

Packaging

- Each hose is bagged individually and boxed. Longer hoses are coiled, bagged and boxed.

Product tests

- Helium leak test (1×10⁻⁵ std cm3/s)

- Additional options: he leak test 1×10⁻⁹ std cm3/s

- Tube adapter

- MFSM (male*)

- MFSF (female*)

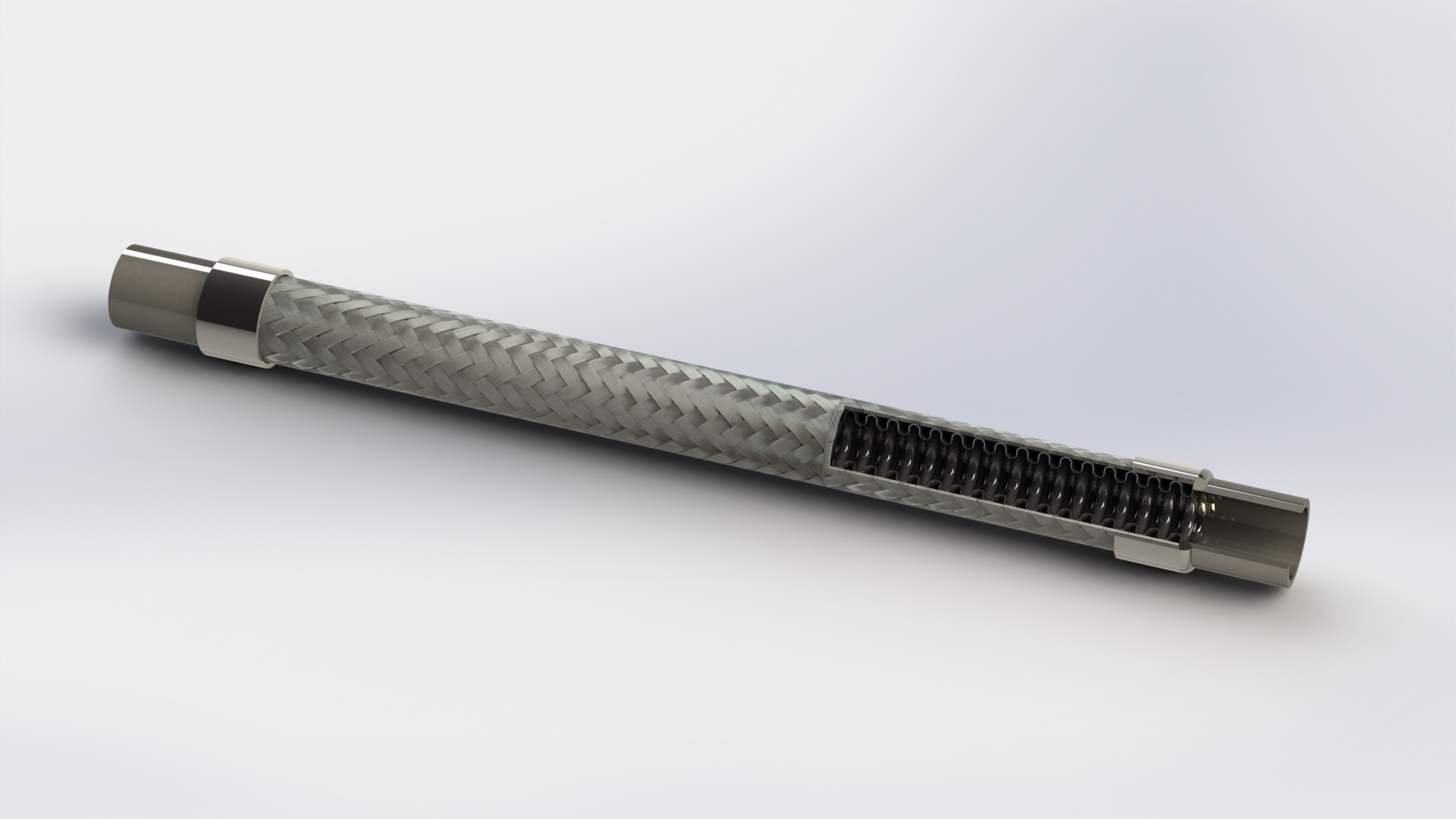

- Highly flexible all-metal hose

- Commonly used in high-temperature or general purpose dynamic-cycling applications.

Our business is designing and producing artery systems that bring machinery to life

As a manufacturer of flexible hoses and Build-to-Spec and Build-to-Print company for artery systems, we partner with clients to optimize supply chains, minimize time-to-market, and share industry knowledge.