Why ultra high purity?

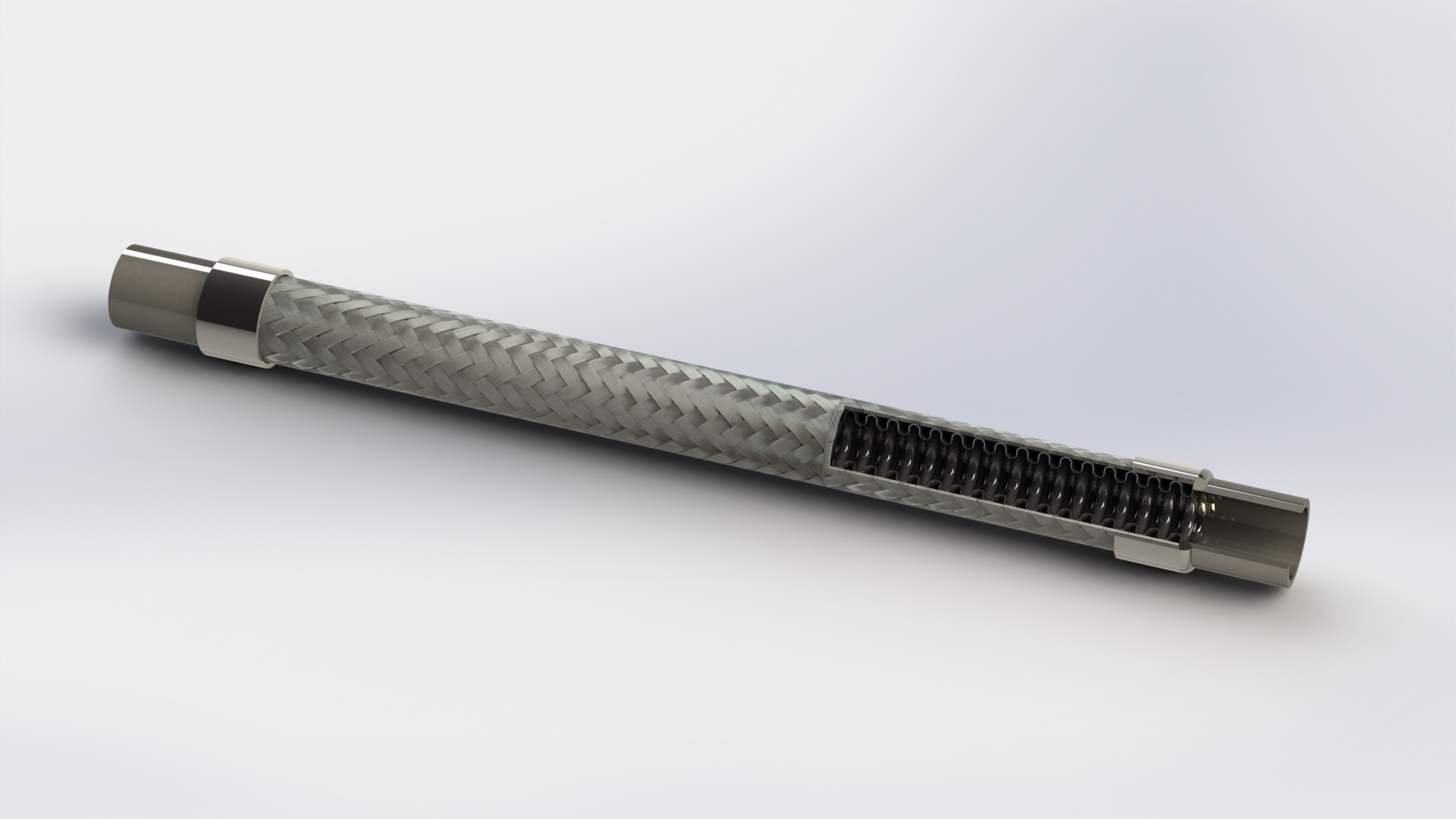

Some systems just need to be very clean and are used in applications outside the machine. This type of high purity piping system is seen to be slightly less critical to an ultra-high purity system, so it therefore needs less validation. A higher level of cleanliness needs a purity hose or system. This is often used inside a machine and closer to the source. In most cases this is a combination between ultra-high purity and ultra-high vacuum. These parts need to be ultra clean. No dirt, no grease, no oil, no stains, no particles, no molecules – absolutely nothing. These high purity systems can transport gases safely and efficiently. You can think of hydrogen, nitrogen, oxygen or helium.